We’ll show you the step-by-step process to achieve a perfectly flat and level underlayment that’s smooth as glass.

Tips and Techniques for Pouring Self-Leveling Underlayment

The Right Floor Leveler Choice for in-Floor Heat

Self-leveling underlayment is a great choice under any tiled floor, but it’s the absolute best choice when installing tile over an in-floor heating system. Installing cement board won’t work, and if you choose to lay down a mortar bed it takes longer, it’s harder to achieve an even surface, and the screeding process can damage the heating cables or mats.

Clean the Floor

Thoroughly sweep and vacuum the entire floor. The floor needs to be primed before adding the floor leveler and you’ll want the primer to soak into the floor, not the dirt and dust sitting on top of it. Keep a marker or roll of tape in your pocket while you’re vacuuming, and mark all the holes or cracks in the wood that will need to be sealed up.

Caulk and Tape Over Holes and Seams

If the liquid leveler is not totally contained, you will end up with a big mess on your hands and probably have to re-pour the floor leveler. Seal all holes and seams in the plywood with caulk. The leveler will drain through an opening as small as a nail hole, so be thorough. A good choice for filling those holes and cracks is the type of caulk that goes on white but turns clear when it dries because you can tell when it is done setting up.

Taping over the caulk isn’t required but it’s a terrific way to avoid stepping in a glob and tracking it around the rest of the house. When working on an older house with floor planks instead of plywood, cover the whole floor in self-adhering roofing underlayment. Looking for more ideas? Check out the benefits of synthetic underlayment over asphalt felts.

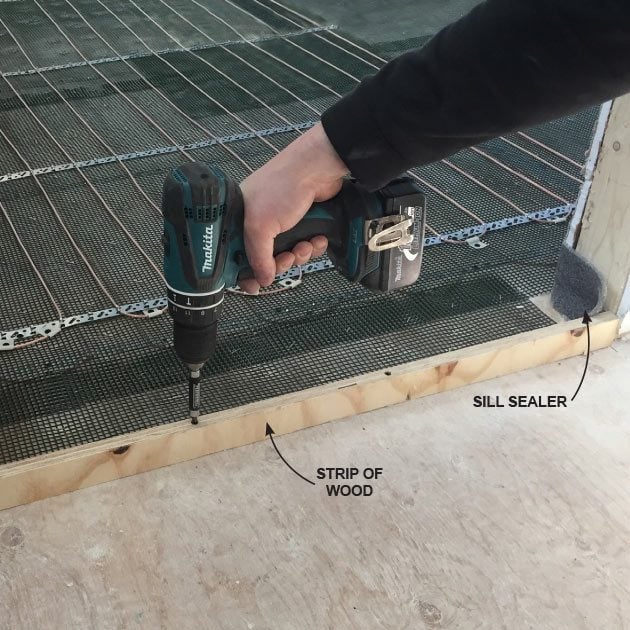

Install Sill Sealer at the Walls

Sill sealer is a foam gasket that framers use to seal the connection between a foundation and the bottom wall plate. Sill sealer also makes a great barrier to keep the liquid underlayment from escaping into other rooms or into the basement on exterior walls. Hold it in place with staples. Keep the staples low enough so the staple holes will be hidden by the base trim. Either 3-1/2-in. or 5-1/2-in.-wide sill sealer will work, but the taller it is, the more protection it provides painted walls from floor leveler splashes.

Caulk the Sill Sealer To the Floor

Smear the caulk with your finger to make sure it adheres to both surfaces. Once the pour is complete the sill sealer can easily be cut flush with a razor. The small void near the wall won’t negatively affect the tile installation.

Install Cardboard Around Vents and Drains

Large holes like heating vents and floor drains can be isolated with cardboard before pouring your floor leveler. Just shape the cardboard to the hole, tape it in place, and then caulk it o the floor. The boxes that hold the flooring are often a convenient source of cardboard.

Build Dams in Doorways

Dam up doorways with strips of wood. Make sure you seal the wood to the floor with caulk as well as the area where the wood strip meets the sill sealer.

Prime the Wood

Wood floors need to be primed before covering them with self leveler. The floor will be covered with water-saturated leveler, which will cause the wood to swell. It will shrink back down when it dries, which could cause cracks in the underlayment and tiles above. The primer prevents the wood from absorbing water. Primer can be rolled, brushed, or even sprayed on with a bottle.

Install the Lathe

Lathe adds strength to the underlayment like rebar adds strength to concrete. Avoid metal lathe when working with in-floor heating. Check with the manufacturer of the heating system whether the lathe should be installed over or under the mat/cables.

- Overlap the lathe at least three inches, and secure it with a tacker hammer stapler.

- Keep the lathe 1-in. or so away from the walls so it doesn’t poke through the sill sealer when installing it.

- Try to keep the lathe as flat as possible so it doesn’t rise higher than the depth of your pour.

- Always check the continuity of the heating cables or mats before you start mixing. If you accidentally sever or nick a cable, it’s a lot easier to repair it before the underlayment is poured.

Order More Floor Leveler Than You Need

Running out of leveler before a pour is finished is kind of a big deal, so don’t do it! Buy 20 percent more floor leveler than you think you need. A large room poured even 1/16-in. thicker than anticipated can gobble up several additional bags of floor leveling compound. Also, bags of leveler can be ruined by wicking up moisture from the ground. Keep your bags dry by setting them on a pallet or a sheet of plywood resting on scrap 2x4s, the same way you would protect bags of concrete mix.

Fill the Mixer Bucket

Keep a bucket on hand to place the mixer in when you’re not using it. Fill the bucket 3/4 full of water. That way the floor leveling compound won’t stick to the paddle and the bucket won’t tip over when you stick the heavy mixer in it.

Prep the Floor Leveler Bags

Most bags filled with dry cementitious mixes have a vent in the top. It’s there so the bags don’t bust open when they’re handled. Minimize the mess produced by floor leveling compound by keeping the vent side up. Line the open bags up next to the buckets. Mixing is a messy business, so do it outdoors whenever possible. Extreme temperatures can affect the time it takes the leveler to set up, so never mix up super cold leveler or work in the blistering hot sun.

Make a Fill Bucket

Make a bucket that can be filled quickly. Fill a clear bucket with the proper amount of water and draw a fill-line with a marker on the outside of the bucket. Another option is to drill holes at the fill-line so the bucket will drain to the proper level. Dipping a bucket into a barrel filled with water is a lot faster than filling it with a garden hose over and over again.

Mix a Bunch of Floor Leveler at Once

Fill all the buckets with the recommended amount of water before you start mixing. Keep the buckets close to each other to reduce the mess when moving the mixer from one bucket to another. Keep all of the bucket handles facing out so they’re easier to grab (every second counts).

Once you’ve mixed all the buckets of floor leveler, go back to the first and mix it up again for a few seconds in order to stir up the sand that settled. Pull the mixer out and set it in the next bucket to be hauled in. After dumping each bucket, fluff up the sand in the next one before hauling it in.

NOTE: Five-gallon buckets are not big enough for mixing self-leveler. Get yourself as many 6-gallon buckets as you can.

Spread as You Pour

Move the bucket along the floor as you pour. Keep the bucket low to minimize splashing. If you do splash on the wall, try to resist the temptation of wiping it off right away because small drops can quickly become large smudges. You’ll have better luck letting it dry and scraping it off.

Completely cover the heating cables/mats with floor leveler to avoid damaging them with a trowel while installing the thin set. The thickness of your pour may vary depending on your project but shoot for a thickness between 1/2 in. and 3/4 in. Anything over 3/4 in. will likely require two pours, but confirm that by reading the instructions printed on the bag of the product your using. Check the thickness with a gauge rake, a junky tape measure or just a Popsicle stick with the desired thickness marked on it.

Move Floor Leveler With a Gauge Rake

A gauge rake is a metal squeegee that rides on two adjustable depth guides. This tool isn’t absolutely necessary, but it does work well at spreading the leveler around, and it helps to “gauge” how thick the self-leveler is. Be careful to work the rake very gently near the heating cables or mat.

Pour Your Way Out

Start at the far end of the room and work your way to the door. If you pass other entry points along the way, make sure to lock the doors and hang “keep out” signs so no one gets stuck in floor leveling compound.

Wash Buckets Right Away

Wash your buckets as soon as you’re done pouring the floor leveler and never dump the dirty water down a drain.