Plywood is a staple material in the construction and woodworking trades. Here's how to recognize the grades and choose among them.

What Are the Different Types of Plywood Grades?

Whether you work in construction or in a wood shop, plywood is a material you can’t avoid. I’ve used it outdoors to sheath roofs and walls, indoors for subfloors and room dividers, and in the shop for multiple cabinet and furniture projects.

Obviously, the plywood you use to make a custom cabinet must be a higher grade than what you use for roof sheathing. But what does the lumber industry mean by “grade,” what are the different grades, and what are they used for?

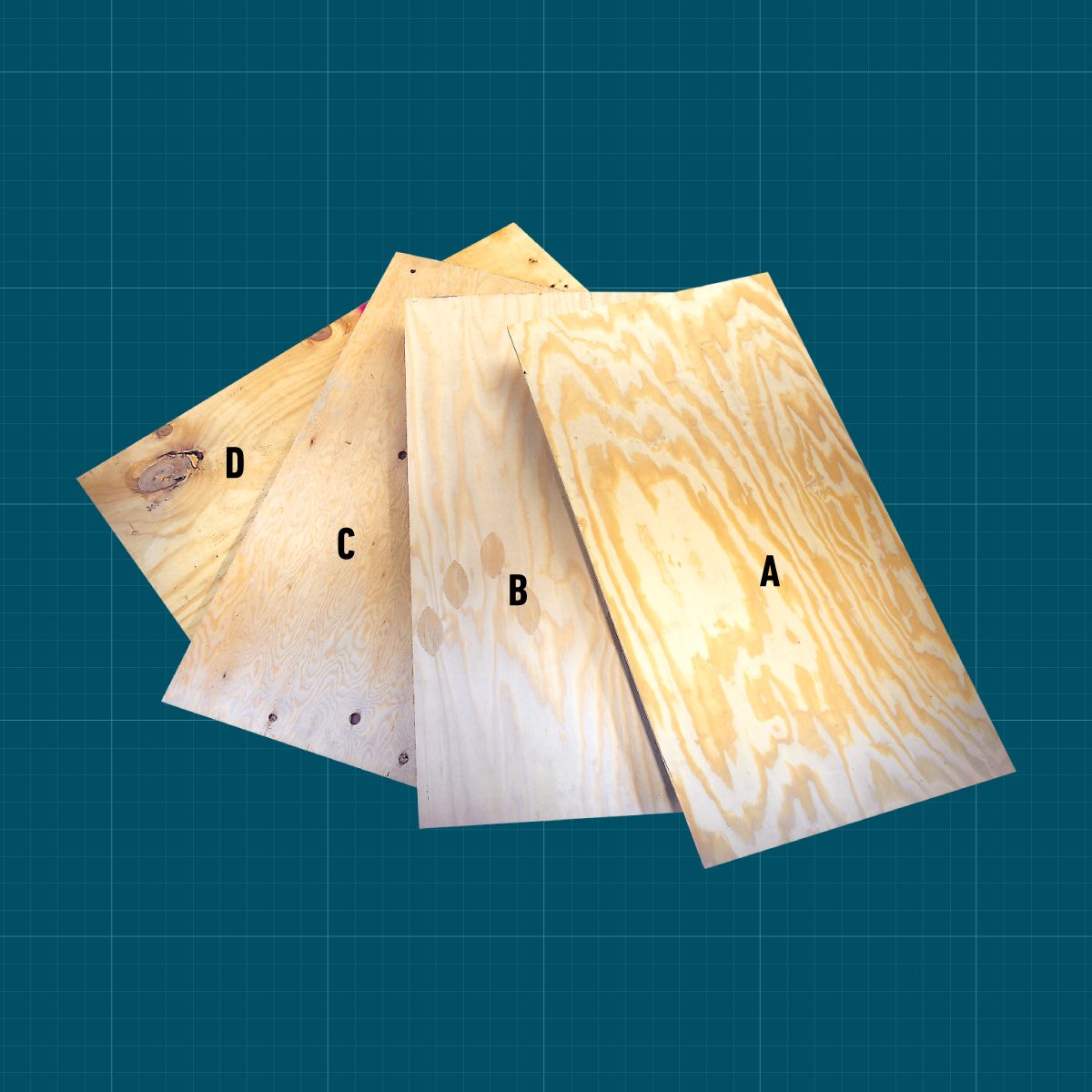

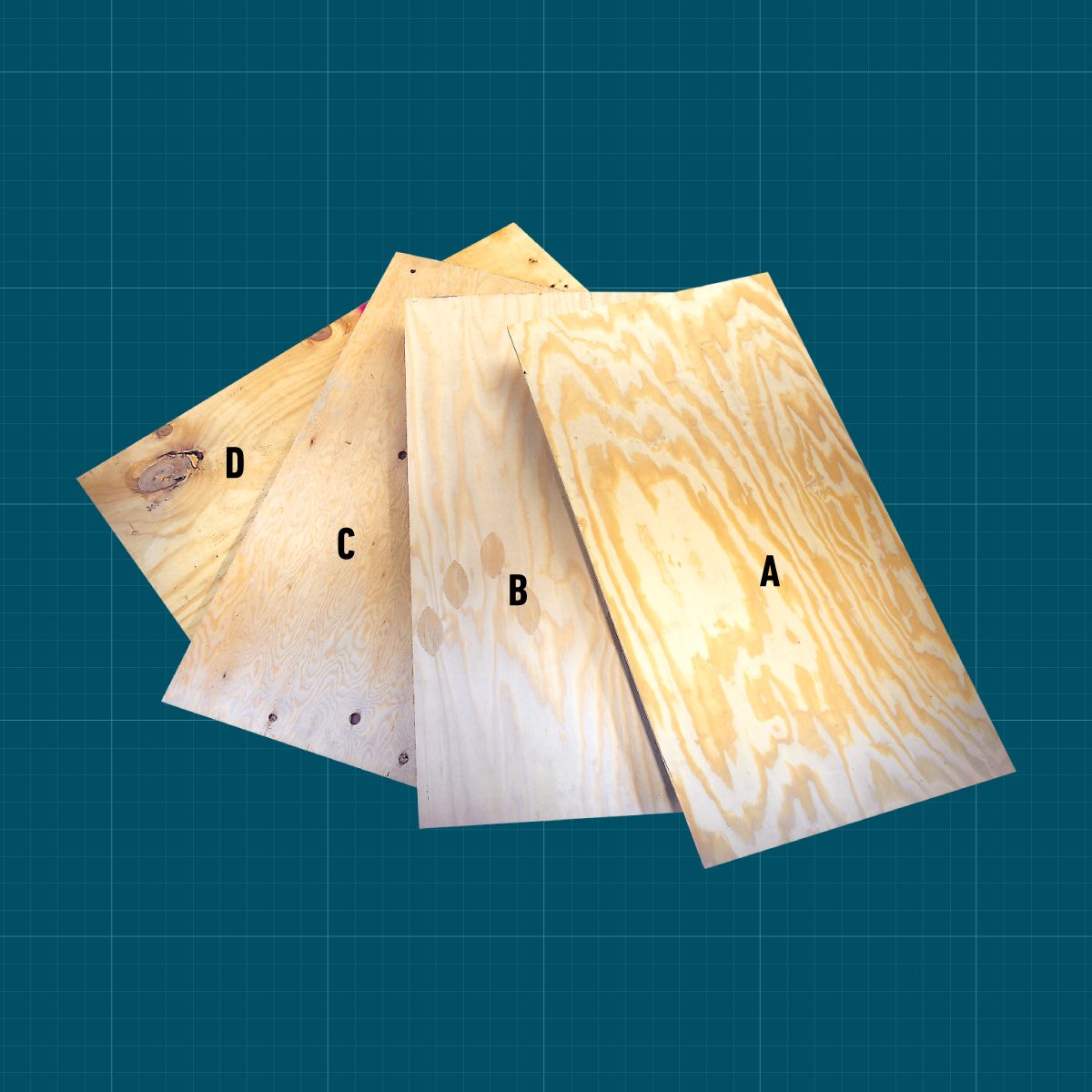

“Plywood is graded through four main levels, A, B, C and D,” says Josh Kou, a lumber pro with a lifelong interest in hardwood.

Grade A is the top grade, and it’s perfect for cabinetry and furniture making. Grade D is at the bottom of the scale. According to Artem Kropovinsky, an interior designer with more than a decade of experience, Grade D is “used for structural purposes where the surface will be hidden.”

Intermediate grades are suitable for some cabinetry projects (mostly Grade B) and other utility purposes (Grade C).

Here’s the lowdown on plywood grading to help you choose the right material for your project.

On This Page

About the Experts

Josh Kou is a second-generation lumber pro who traveled extensively through Asia learning woodworking techniques. He’s the operations manager for NorthCastle Hardwoods.

Artem Kropovinsky is an interior and cabinet designer and the founder of NYC-based Arsight. His designs have been featured in Architectural Digest, The New York Times, Forbes, Business Insider and Domino. He has extensive knowledge of plywood and its uses.

What Is Plywood?

Slice wood from a tree trunk in thin layers, glue them together in alternating directions, and you’ve got plywood.

“Almost all plywood in the U.S. is made from either Douglas fir or western larch, both of which are softwoods,” says Kou. “However, Grade A plywood is often finished with a hardwood veneer. It is an affordable and sustainable way to present hardwood.”

Plywood comes in sheets measuring four by eight feet (1,220 x 2,440 millimeters), in thicknesses ranging from 1/4-in. (6-mm) to 1-3/16-in. (30-mm).

Because wood layers are glued in cross directions, plywood is more stable than solid wood and rarely warps or buckles. This makes it a good alternative to solid wood for construction and cabinetry, and often the preferred material.

What does RTD stand for on plywood?

RTD stands for “Resistance Temperature Detector.” Manufacturers monitor the temperatures of each layer during production of RTD plywood, ensuring a more reliable glue bond and a better-wearing final product.

What is marine grade plywood?

A product where manufacturers use a waterproof adhesives and wood preservatives to make highly moisture-resistant sheets. The veneer may be a hardwood or softwood, and it must be free from defects.

As the name suggests, boat builders use this type of plywood. Contractors like it for sheathing and subfloors in areas subject to excessive moisture.

What is exterior grade plywood?

Identified by the rating X, this product is also moisture-resistant. But manufacturers use lower-grade adhesives to produce it, and the softwood veneer may have knots and other defects.

Plywood Grades Explained

The four plywood grades are as follows:

- Grade A: “This is top-tier,” says Kropovinsky, “with a smooth, sanded surface free of knots. Ideal for visible surfaces in cabinetry or furniture.”

- Grade B: Slightly lower quality than Grade A. Grade B may have minor blemishes but still offers a good, smooth surface for painting or veneering. “It’s not top drawer,” says Kou, “but it’s perfectly serviceable.”

- Grade C: This grade comes with noticeable defects and knots up to 1-1/2-inches. According to Kropovinsky, it’s suitable for structures that require strength but don’t have to look good.

- Grade D: The lowest grade, with knots and defects up to 2-1/2-inches. Grade D is generally used for structural purposes where the surface will be hidden. Kou recommends Grade D when “it doesn’t matter what it looks like as long as it can roll with the punches and take a beating in transit.”

Plywood sub-grades

Both sides of a sheet don’t always have to be the same quality, because in many applications only one side is visible. Here’s Kou’s rundown of uses for the most common sub-grades:

- AA: Sanded and defect-free on both sides and suitable for interior work, like furniture, cabinetry and any other application where a good finish is required.

- AAX (AA Exterior): Use for sign boards, boxing, boats and any other exterior use where a high level of finish is required to both faces of a panel.

- AB: Perfect when only one side of the finished product needs to have a top-quality finish. Sometimes used in cabinetry as drawer bases with the A-graded side face up. This is my most common choice for a cabinet material.

- ACX: Perfect for areas exposed to high levels of moisture where a smooth surface is required for practical, or cosmetic reasons. ACX is most commonly found in soffits under your roofline, in truck and boxcar linings, farm buildings and commercial refrigerators.

- BB: A standard utility grade for everyday internal use that can be paint-finished. You’ll find a few minor repairs to the face using patches or wood filler and a few tight knots. I’ve made perfectly serviceable cabinets and furniture from this stuff.

- BBX: A good solid workaday board ideal for many external applications like shed and barn walls. There’s a pre-oiled version for concrete forms that can be cleaned and reused.

- BCX and BDX: These make good truck linings and tanks, and builders use it as a base for exterior coatings. Great as utility panels for industrial shelving where a decent top finish is required, or as bins where an interior finish is not important.

- CC: This is tough stuff. It’s used for flooring in boxcars, trucks, external decking, balconies, cable reels, shipping pallets and other utility applications.

- CDX: This is the most common roofing and exterior sheathing material. “It’s suitable for exterior use due to the adhesive used in its manufacture,” says Kropovinsky. The C side typically faces out.

What’s the best grade of plywood?

For quality, AA, but it really depends on the use. If you’re doing outdoor building, AAX, ACX and BCX are preferable.

What’s the most expensive plywood?

Again, that’s AA. A single 4- by 8-ft. sheet of 3/4-in. maple-faced plywood, sanded on both sides, costs almost $90. By contrast, a 3/4-in. sheet of utility-grade CDX plywood costs less than $60.

What is cabinet grade plywood?

For clear finishing, any plywood with one A-grade face is suitable for cabinets. For painting or veneering, you need at least one B-grade face.

What is furniture grade plywood?

Same answer. You need at least one A-grade face for clear finishing and one B-grade for paint or veneer. For exterior furniture, use AAX, ACX or BCX.