PEX tubing is an easy-to-install alternative to copper pipe. Long used in radiant heating systems, flexible PEX tubing is perfect for water supply lines because it’s easy to run through walls and floors and simple to work with.

A Guide to Plumbing With PEX Tubing

The Advantages of PEX

Use the Same Stuff

There are several different manufacturers of PEX. It is very important that you know which brand of pipes you're working with and install only that manufacturer's connectors and fittings. If you mix and match materials, you will void your warranty and may fail your inspection. Worst-case scenario: You'll end up with leaky pipes and water damage. Not all products have recognizable markings on them, so leave a few of the packaging labels on-site to appease the inspector and for future reference.

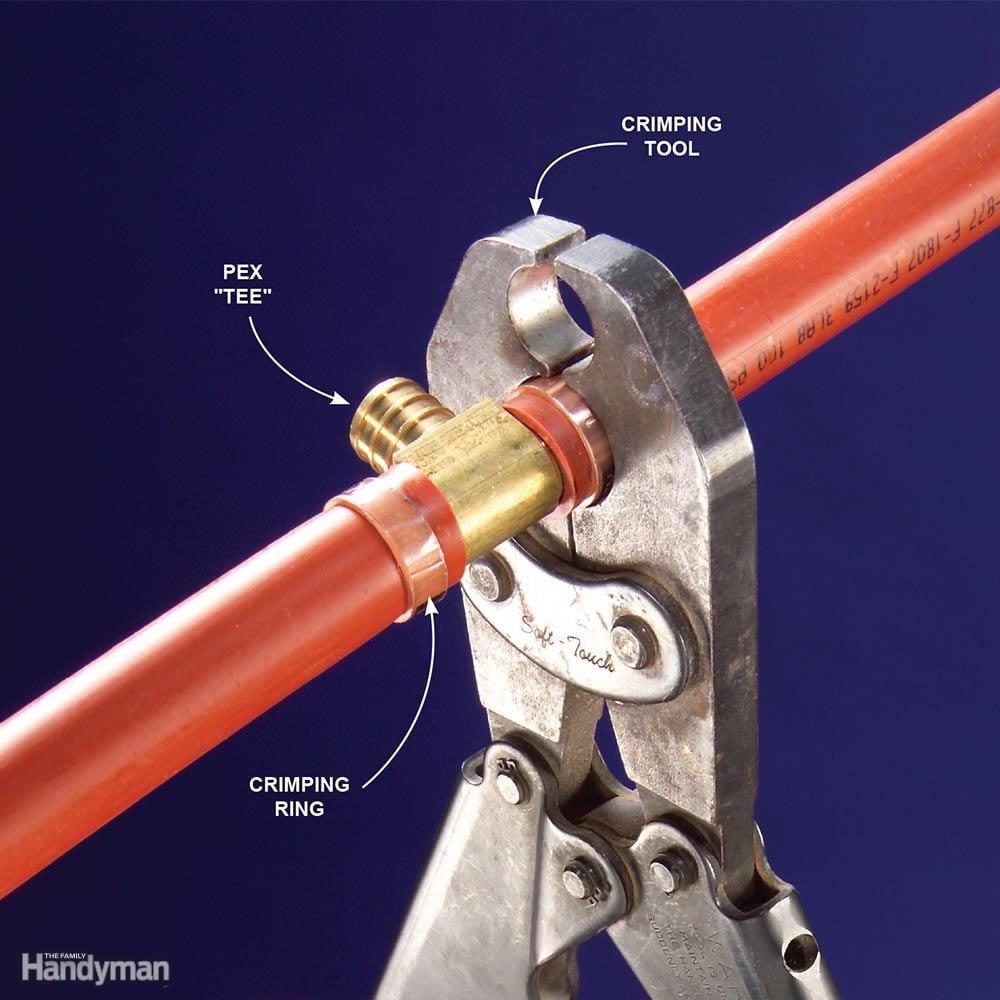

Make Crimped Joints at PEX Water Line Fittings

PEX Cutter

Cut the PEX off perfectly square for leakproof joints. PEX cutters like this Plastic Pipe and Tubing Cutter are available at home centers and online.

Stab-In Fittings

Use stab-in fittings only where you have access to the joint. These fittings don't require a special tool. You simply push the pipe into the openings. Press the outer ring onto the fitting to release the pipe.

Cinch Clamps Are Easy

There are many different ways to connect PEX to fittings, but cinch clamps are one of the easiest. They're readily available and relatively inexpensive, and you know when they're installed properly because the tab of the clamp will be visibly pinched.

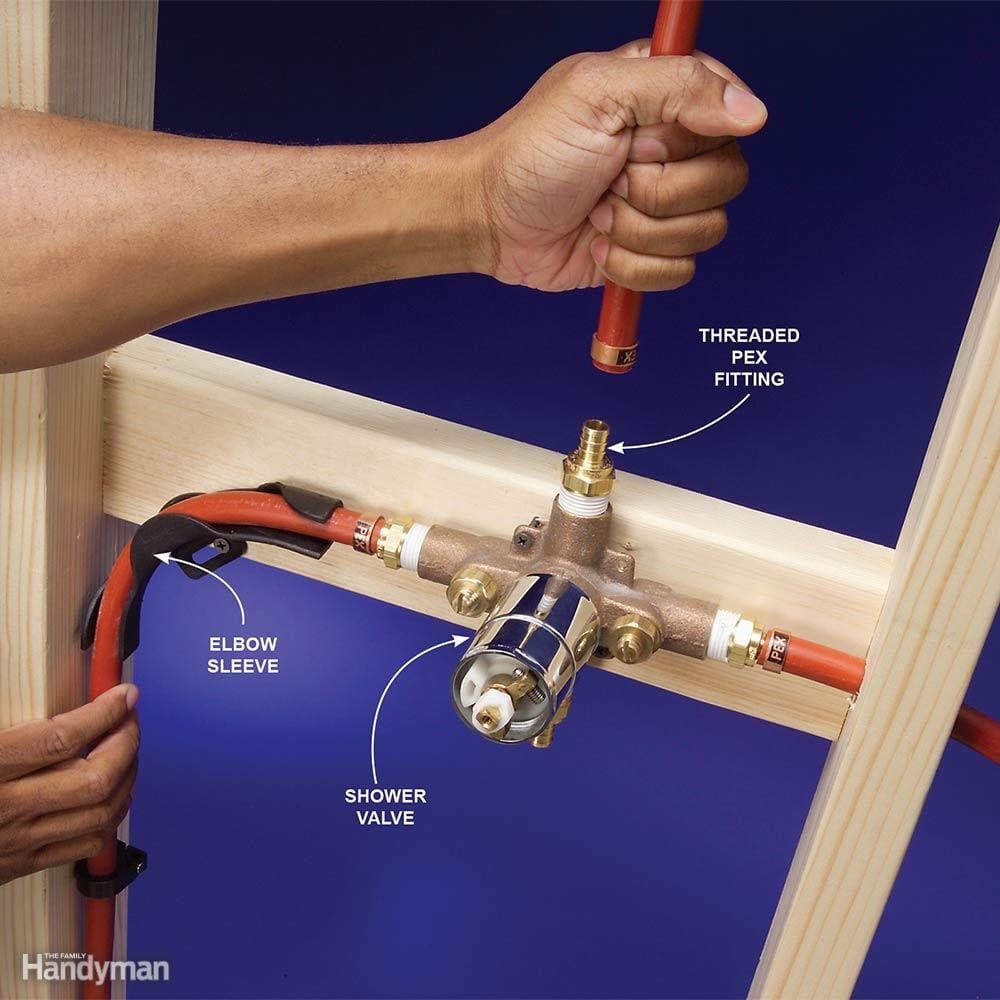

Fittings for a Shower Valve

PEX Shutoff Valves

Drop-Ear Elbow

Use drop-ear fittings designed for PEX for shower arms and tub spouts.

Repair or Replace Kinks

Kinks happen. You can repair kinks with a heat gun, but PEX tends to rekink in the previously kinked spot, especially if the pipe needs to make a bend at the kinked location. It's best to cut kinks out and use the shorter sections of pipe elsewhere. If you get a minor kink in the middle of a long, straight run and you don't want to cut it out, heat the pipe with a heat gun and then cover the damaged area with a hanger or abrasion clip. That will help the pipe keep its shape.

Protect Your Pex

Abrasion and Suspension Clips

If your pipe is in contact with a joist, duct, electrical box or steel stud, or it is passing through a block wall or concrete slab, it needs to be protected with an abrasion clip or a suspension clip.

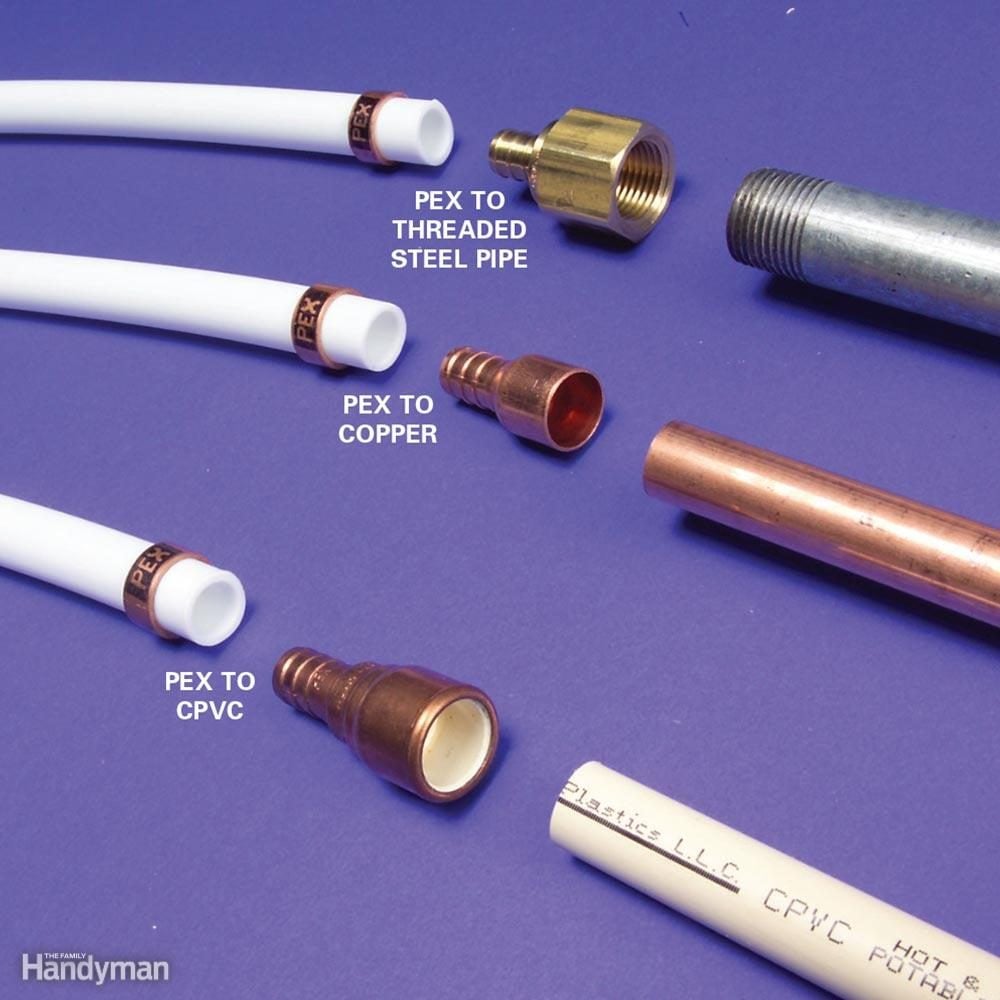

Transitions to Other Types of Pipe

Run the Line Without Joints

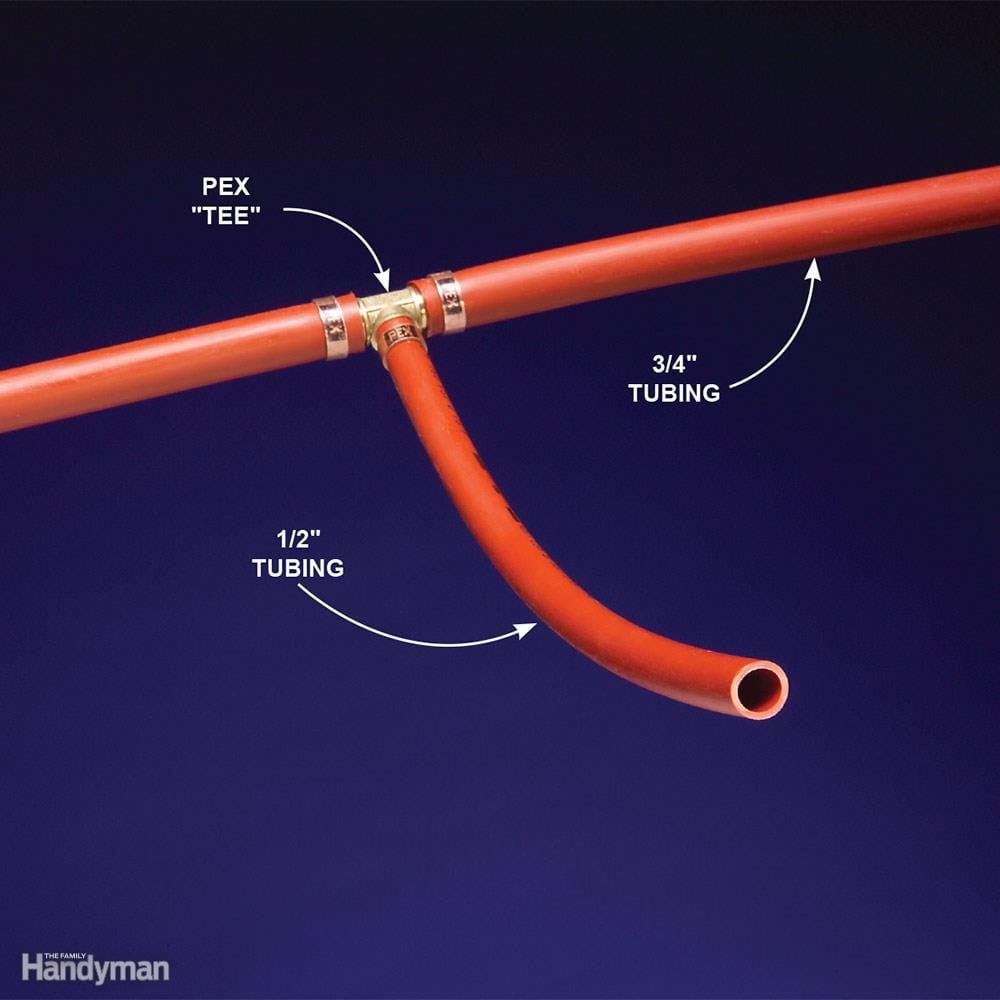

You can run PEX line as you would in a conventional plumbing system, with 3/4-in. main lines and 1/2-in. branch lines. You can also use a “manifold” system, where you run a 1/2-in. line to each fixture from a central spot.

Run your main lines first. If you're running PEX through joists or studs, drill 3/4-in. holes for 1/2-in. piping and 1-in. holes for 3/4-in. piping. Have a helper feed the line to avoid kinks and snarls. Some manufacturers recommend adding abrasion clips at each hole. You must use them for PEX that goes through metal studs, and nail protection plates when the tubing runs within 1-1/2 in. of the face of a stud or joist. Once you've run your main line, go back and mark the location of each branch line, leaving a 1-in. gap for the barbed tee.

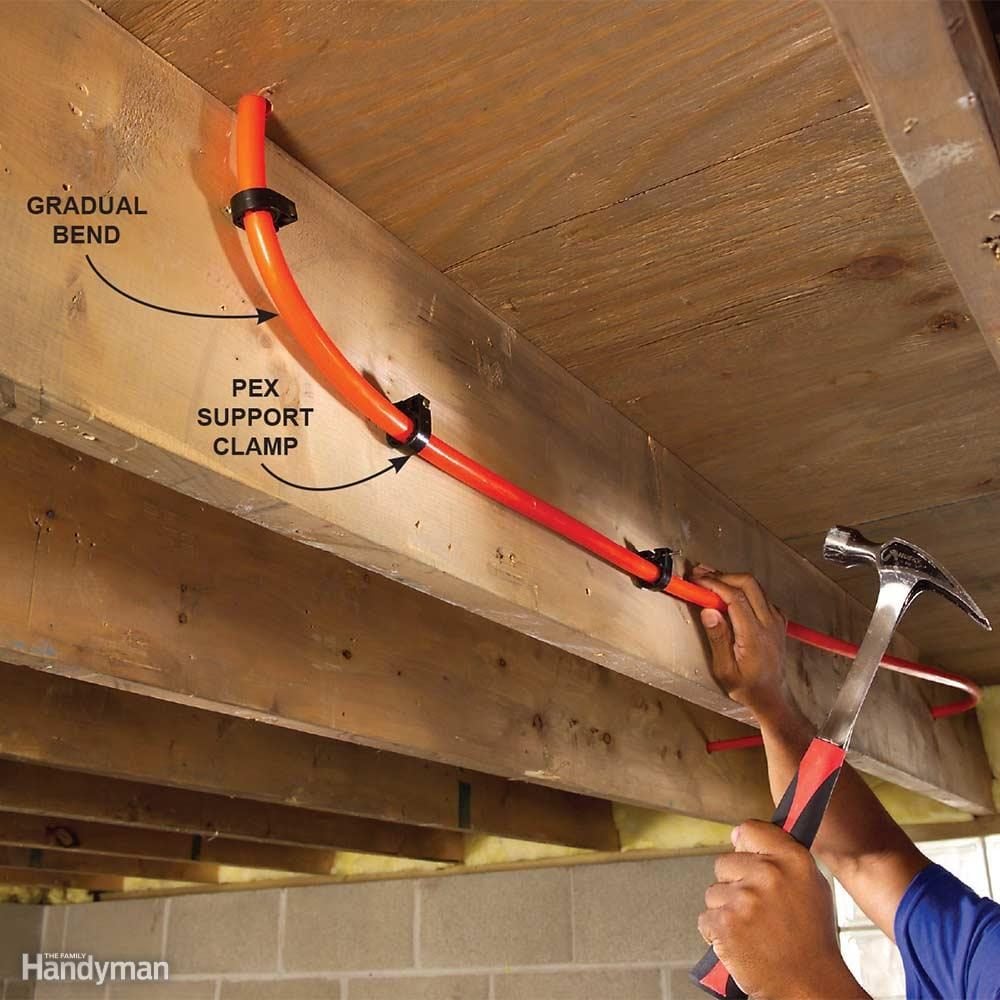

Support Long Runs

Where the pipe runs along a surface, be sure to support it every 16 to 24 in. with special PEX clamps to reduce sag.

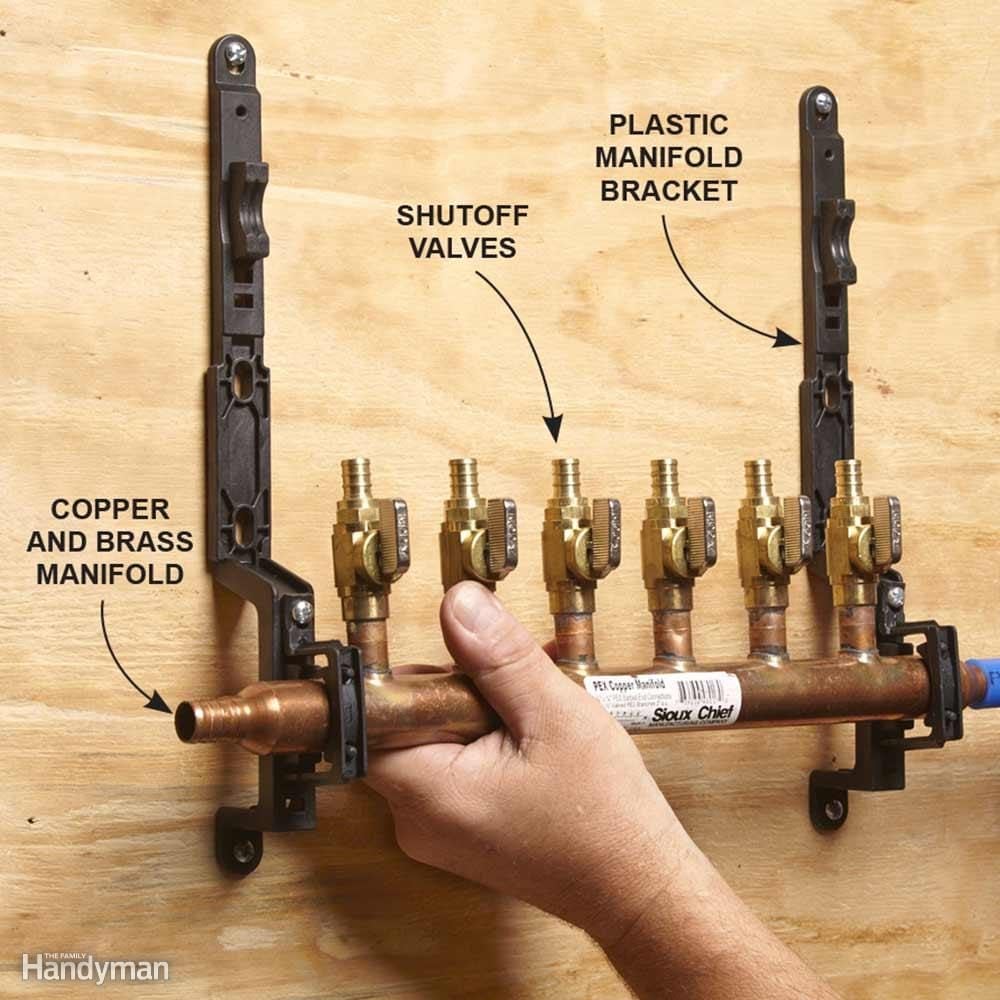

Home Runs Are Best

You can install PEX with main lines and branches to each fixture, but “home runs” are better. A home run is one line that runs directly to a fixture, starting at a manifold. Home runs require more piping but deliver a stronger and more consistent water flow. Also, installing home runs is fast and requires only two connections (one at the manifold and another at the fixture end), which reduces leaks.

You can also use a hybrid system where you run 3/4-in. hot and cold lines to a set of fixtures—for example, in a bathroom—and install a smaller manifold behind an access panel. Then make short runs of 1/2-in. lines to each fixture. Another cool thing about home runs is that each fitting has its own shutoff at the manifold. That means you can shut off just that fitting to do some work—you don't have to shut off the water to the whole house.

Upsize to Avoid Poor Pressure

The inside diameter of 1/2-in. PEX is smaller than that of 1/2-in. copper (and even smaller with fittings). If you're tearing out copper and replacing it with the same size PEX pipe, the water flow to the fixtures may be noticeably lower when you're done. If you're working on a house that has less than 45 lbs. of pressure or a flow rate of less than 4 gallons per minute, make sure you install home runs, and consider going up in size to 3/4-in. pipe. A simple way to test water pressure is to hook up a hose bib pressure gauge (sold at home centers) to your spigot. To check your flow rate, just see how many gallons of water flow into a 5-gallon bucket in one minute.

Control Your Coil With an Elastic Cord

Warm up Cold Pipes

Our plumbing expert, Les, knows a plumber who did a job in northern Wisconsin in the middle of winter. The building had no heat, and all the pipes and fittings were freezing cold. When the furnace was fired up and the water turned on, they sprang dozens of leaks. Most PEX manufacturers recommend you work with pipe at temperatures above freezing. The whole length of the pipe doesn't need to be warm, just wherever you make a connection. You can heat those cold pipes and fittings with a heat gun or hair dryer, leave them in a warm vehicle for a while or keep fittings in your pocket. Heck, you can even warm a pipe in a thermos of hot water.

Plan for Stub-Outs in Advance

There are a couple of options for bringing PEX out through a wall (stub-outs). If the piping is going to be exposed, say for a pedestal sink or a toilet, buy a copper stub-out and crimp it onto the PEX. Then use standard shutoff valves. If the stub-out will be hidden, inside a cabinet, for example, or you don't mind the look of exposed PEX line, use a barbed PEX shutoff valve.

Whichever method you use, be sure to add a couple of extra fasteners next to the stub-out to increase stability.

Use Angle Fittings for Tight Turns

Don't take a chance on crimping the PEX at corners. Make tight turns with 90-degree angle fittings.

Install PEX Directly to the Fixtures

Many plumbers prefer to run PEX directly to the fixtures so they don't have to bury fittings behind the walls. It's hard to keep PEX perfectly straight when PEX exits the wall, so another option is to use a 90-degree copper stub-out when you run a line to a toilet or other fixture where your shutoff valve will be visible.

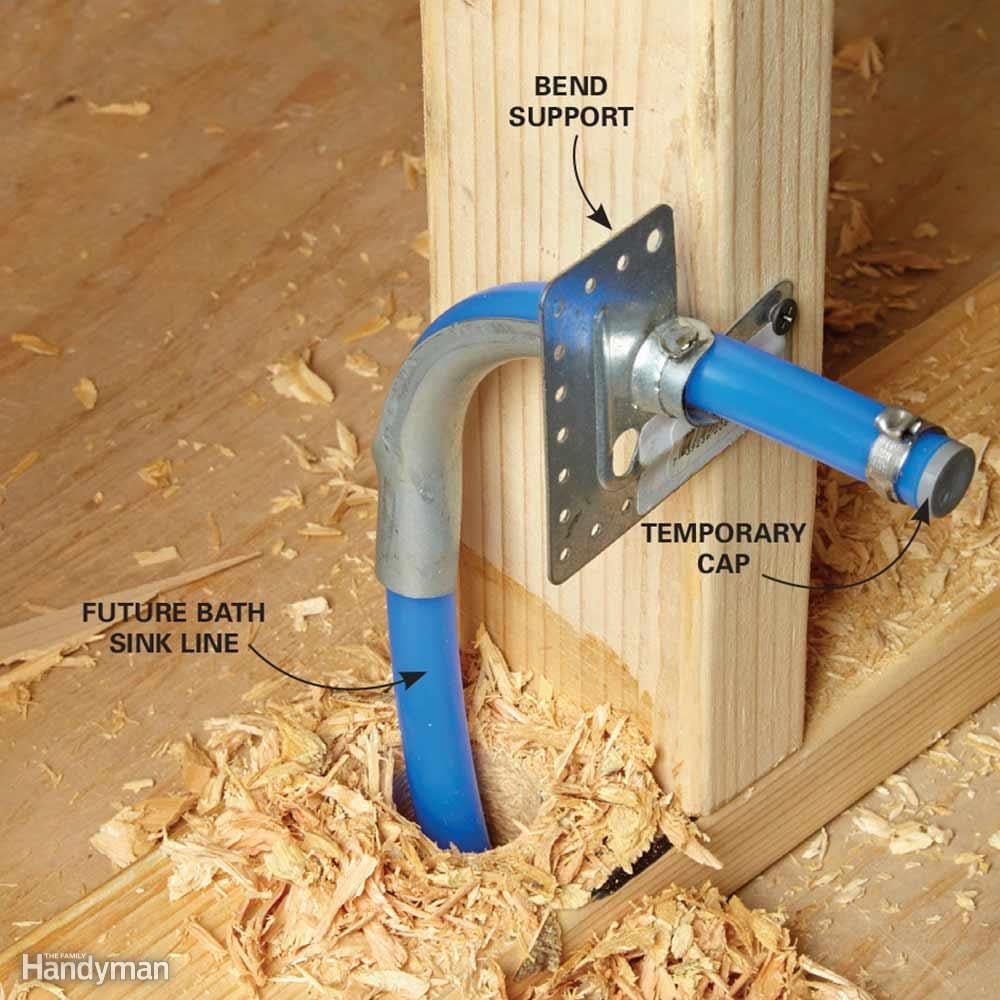

Avoid Kinks at Tight Corners

PEX's flexibility makes it easy to work with. It can be bent around pretty sharp corners without the need for an elbow fitting. But if you try to bend it too much, you'll end up kinking it. Installing a bend support will prevent this, and it will also protect the pipe from abrasion.

Keep PEX Away From Hot Stuff

Also, look into these plumbing terms to understand plumbing better.