Everything you wanted to know about breaker panels and more. A veteran electrical inspector answers your questions.

Electrical Questions Answered By An Electrical Inspector

Electrical Panel Clearance Requirements

Question: What are the working clearance requirements around the location of an electrical panel?

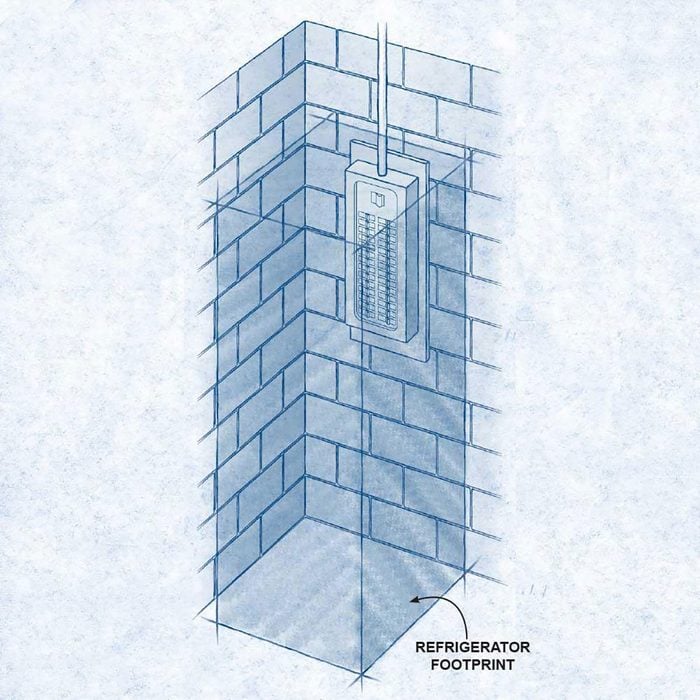

Answer: Visualize your favorite refrigerator; the volume of space that would be needed by a refrigerator is about how much working clearance you need in front of an electrical panel. Here are the basics for a dwelling; both access to the working space, and the actually working space are required. The depth of the working space is 36 inches. The width of the working space must be at least 30 inches, or the width of the panel, whichever is greater. However, the panel is not required to be centered on the working space, it could be offset to one side or the other. But, the width of the working space must allow for the panel door to open at least 90 degrees. The height of the working space must be at 6-1/2 feet. Find out the cost to replace an electrical panel.

Other electrical equipment located above or below the panel cannot protrude more than 6-inches beyond the front of the panel. The space equal to the width and depth of the panel extending from the floor to the structural ceiling is dedicated for electrical equipment; that means no plumbing or gas pipes, no ductwork, or any other foreign equipment. These clearances are designed to protect the person working on the panel. It’s difficult to work safely when your arms are pinned to your sides.

Also, panels need to be readily accessible, meaning the area should not be used as storage space, be located over the steps of a stairway, or require a ladder for access. They also cannot be installed in the vicinity of easily ignitable material, such as in clothes closets, and they are not allowed to be installed in bathrooms (where the moisture would create serious corrosion issues).

Subpanel Power Supply

Question: Can a subpanel have power supplied from a circuit breaker into another subpanel? In other words, can you daisy-chain subpanels?

Answer: In short, yes.

The main electrical service panel is where branch circuits originate. A branch circuit consists of the circuit conductors between the final over-current device protecting the circuit and the lights, receptacles and equipment supplied by the branch circuit.

There are three main types of branch circuits:

- General-purpose branch circuits for illumination and other general purposes

- Appliance branch circuits that supply power in the kitchen for countertop receptacles, such as small appliances

- Individual branch circuits that only supply one utilization equipment, such as a central heating gas furnace, an electric clothes dryer, an electric range and so on.

The main service panel also may contain fuses or circuit breakers that supply “feeder” conductors to downstream subpanels. A feeder consists of the circuit conductors that originate at the main service panel and are routed to the subpanel, in which there are branch circuit overcurrent devices for the downstream branch circuits.

You could daisy-chain a feeder from the main service panel (Panel A) to a subpanel (Panel B), and then run another feeder from Panel B to another subpanel (Panel C). There really is no limitation to this concept, as long as every set of feeder and branch circuit conductors are properly sized and rated in amperes, and each feeder and branch circuit has the proper over-current protection (fuse or circuit breaker). Learn how to install and wire a subpanel.

Electrical Panel Locations

Question: Can an electrical panel be installed in a bathroom?

Answer: Do not install an electrical panel in a bathroom.

All electrical conductors, equipment, light fixtures and so on must be identified for use in the operating environment in which they will be installed (indoor dry locations, indoor or outdoor wet locations, hazardous [explosive] location inside a vehicle paint spray booth, etc.). There is a basic rule in the code that says unless otherwise approved and marked accordingly, no electrical conductors or equipment are permitted to be installed in damp or wet locations, locations exposed to gases, fumes, vapors, liquids, other deteriorating agents, or locations exposed to excessive temperatures.

Electrical conductors and equipment that are rated for dry, indoor locations free of any corrosive effects obviously would be the most economical to purchase. Do they make equipment for corrosive locations, such as inside your favorite drive-through car wash? Yes, but it’s going to be much more expensive. It’s always best to plan and layout every installation in such a way that the electrical equipment is located where it is protected and kept dry, and then minimize the quantity of electrical wiring that is extended into the less desirable locations.

Which Panels are Approved for Double-Lugging?

Question: How do you determine which electrical service panels are approved for terminating two neutrals together under one screw terminal, or one neutral and one equipment grounding conductor under one screw terminal, often referred to as “double-lugging”?

Answer: As they say, the devil is in the details.

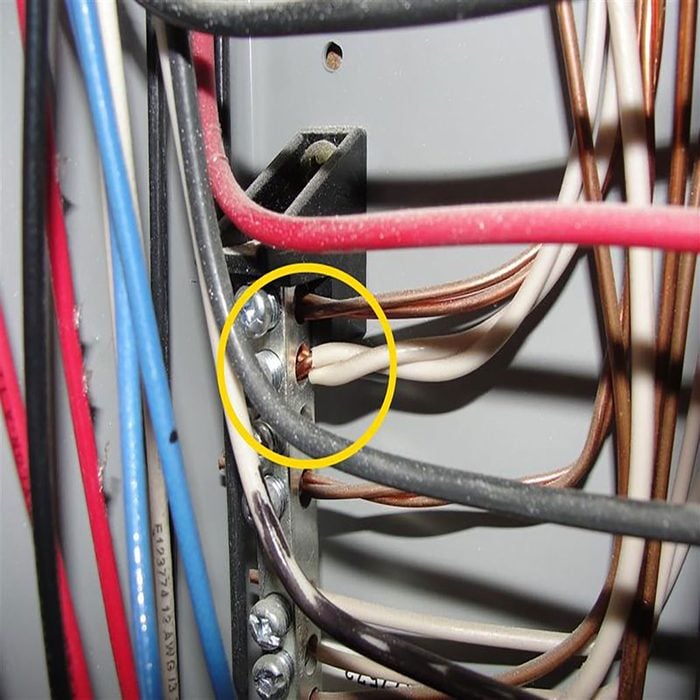

First of all, neutral conductors can never be doubled-up under one terminal; the code has specifically prohibited this practice since 2002. For other terminations, the electrical code has a very basic rule; terminals for more than one conductor must be identified. Space is limited on terminals due to their small size; it’s more important for that precious real estate on a terminal to be marked with the size of conductors, whether it’s approved for copper or aluminum, the temperature rating, etc.

There’s not much room left for identifying whether or not the terminal is approved for more than one conductor. Often you have to look at the terminal or circuit breaker packaging, product wiring diagrams, the manufacturer’s label inside the electrical panel, a product specification sheet from the terminal or circuit breaker manufacturer, online at the manufacturer’s website, etc. It inevitably requires some detective work unless the electrical panel or packaging is clearly marked, and different brands of terminals and circuit breakers have different allowances.

When in doubt, don’t “double-lug” two conductors under a single terminal. It’s a favorite violation that gets flagged by private home inspectors when homes are being bought and sold.

Labeling Circuit Breakers

Question: Does the electrical code require that electrical panel circuit breakers be labeled?

Answer: Absolutely.

There is no gray area here. Labeling a new electrical panel only takes a few minutes. Tracing circuits and labeling an existing panel is a task that is best done with two people and could take hours. A complete directory helps to ensure the safe operation of the electrical system, especially in an emergency. The code requires that every circuit and circuit modification be legibly identified as to its clear, evident and specific purpose or use. The identification must be included in a circuit directory that is located on the face or inside of the panel door. The circuit directory must be durable enough to withstand the environment in which it is located.

Each label identification must contain a degree of detail that distinguishes it from all other circuits. Even spare, unused circuit breakers must be identified. And don’t create personal labels such as “Mary’s Bedroom” that will have no meaning to the next family that owns the home.

Kitchen Countertop Outlets

Question: What are the receptacle outlet spacing rules for kitchen countertops?

Answer:

Here are the basics: A receptacle outlet needs to be installed on each wall where the countertop or workspace is 12 inches or wider. This makes sense because even a 12-in. space can accommodate a toaster, coffeemaker, or other small appliance.

Receptacle outlets need to be installed so that no point along the wall line is more than 24-inches (measured horizontally) from a receptacle outlet in that space. In other words, an appliance with a 24-in. cord could be placed anywhere along the countertop, and the supply cord could reach a receptacle outlet in either direction. Countertop spaces interrupted or separated by built-in rangetops, sinks, refrigerators, etc. are considered separate countertop spaces and require a receptacle outlet.

Whole Home Surge Protectors

Question: Would you suggest having a whole home surge protector installed in the main service electrical panel?

Answer: It’s a smart idea! Appliances, computers, entertainment devices, lighting controls, and HVAC are just some of the systems controlled by sophisticated and sensitive electronics. Replacing these devices that have been damaged in a power surge has become such an expensive issue for homeowners and insurance companies that there is a proposal for the upcoming 2020 National Electrical Code to require a Type 1 or Type 2 surge protective device at the service panel for every new dwelling unit. This proposed rule will also require a surge protective device to be installed when an existing service panel is replaced.

And as we transition to distributed generation resources (DER) like wind and solar photovoltaic (PV) it will be even more important to provide surge protection for our equipment and systems. More information about the different types of surge protectives can be found in the 2017 National Electrical Code in Article 285. Here’s what you need to know about smart electrical panels.

Burying Dead Wires

Question: Is it acceptable to leave a dead wire buried in the wall, when removal is not possible or very difficult to accomplish?

Answer: Yes.

If the wiring method consists of raceways, such as rigid or flexible metallic or nonmetallic conduits, abandoned, discontinued or disconnected conductors should be removed. For cable-type wiring methods, abandoned cables that are accessible and are not terminated at a piece of equipment or tagged for future use should be removed. When it comes to cables that are not accessible, common sense really comes into play. Both ends of the cable should be cut back in such a manner that they can never be accidentally used again or worse yet become energized, which obviously would create a serious fire or life safety hazard.

Nonmetallic Cable Ties

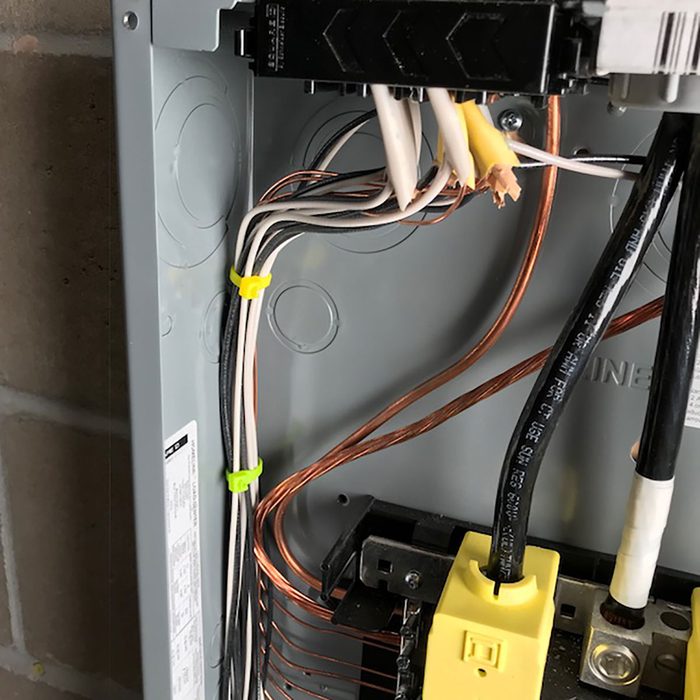

Question: Is it okay to use nonmetallic cable ties (zip ties) in an electrical panel?

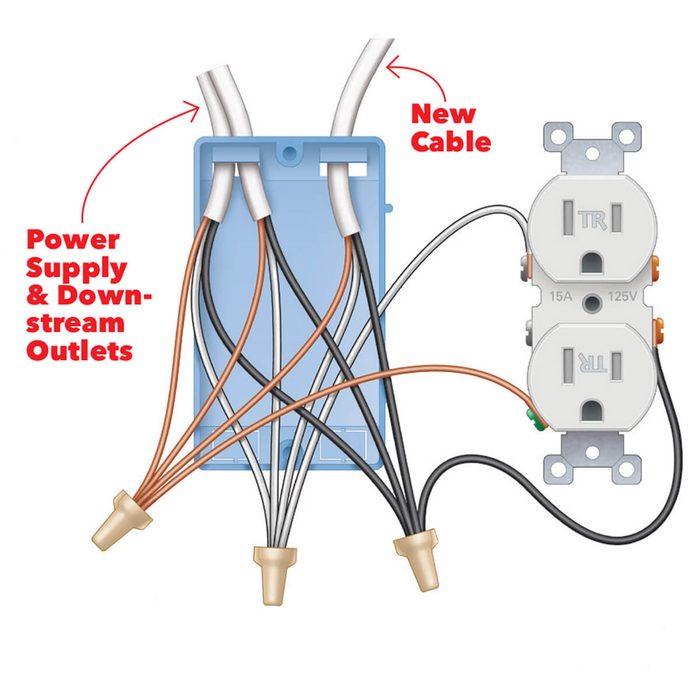

Answer: Sure, they are a great way to keep conductors tidy, grouped together and you end up with a professional-looking project. In fact, where you have multiple neutrals in an enclosure with different circuits, you need to group the corresponding neutrals and hot conductors together, and using nonmetallic cable ties is an easy way to accomplish this task.

Ufer Ground Location

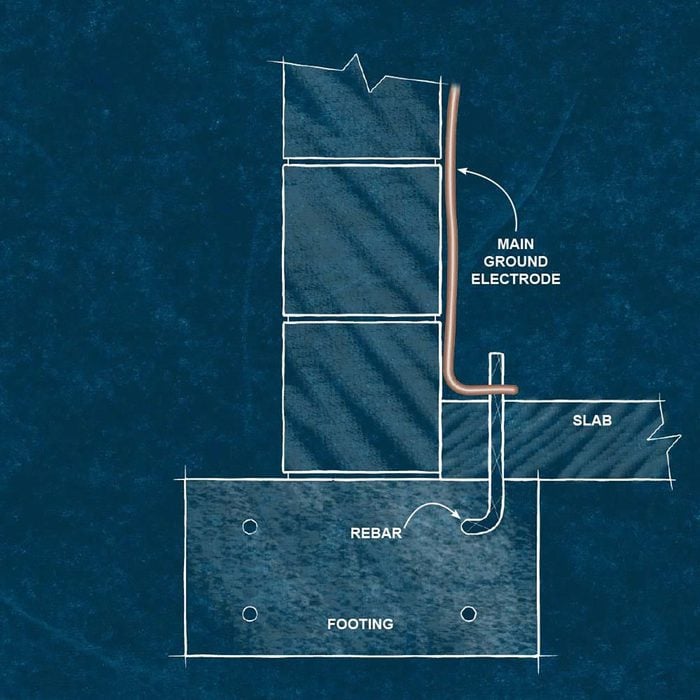

Question: How far can the concrete-encased grounding electrode (aka Ufer Ground) be from a main service panel?

Answer: There is no distance criteria for concrete-encased electrodes (no minimum or maximum distance from the electrical service panel). If present at a building, then a concrete-encased electrode (CEE) is required to be part of the grounding electrode system for the building. In other words, you are not required to install a CEE, but if one is present, it must be used as part of the grounding system.

A CEE consists of at least 20 feet of ½-in. or larger bare conductive steel reinforcing bars or rods installed in one continuous length, or in multiple pieces tied together with the usual tie wire, exothermic welding, approved clamps, or other effective means, with the goal of creating an overall length of 20 feet or more. Another option is to use 20 feet of a bare copper conductor not smaller than #4 AWG embedded in the concrete. The rebar or bare copper conductor must be encased by at least 2-inches of concrete and needs to be located horizontally in the footing or foundation that is in direct contact with the earth.

But wait…what the heck is a Ufer Ground anyway? Well, during WWII Herbert G. Ufer discovered that a CEE is a much better electrode than driven ground rods, especially in dry desert regions, so eventually, the “Ufer” Ground found its way into the National Electrical Code.

Where to Install GFCI Protection

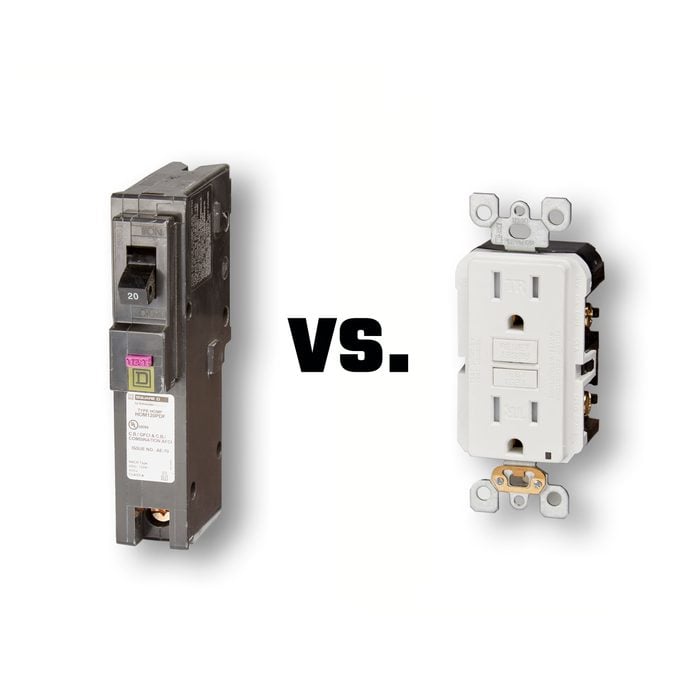

Question: Is it better to install a GFCI protection device in the panel or in a receptacle?

Answer: It’s amazing that GFCI devices have been around 50 years! Just about every region has some sort of requirement for ground-fault detection, and thousands of lives have been saved around the globe.

Many GFCI options are available today, but the two most common types are GFCI circuit breakers and GFCI receptacles. You do not need both on the same circuit. A GFCI circuit breaker protects the entire branch circuit and everything connected to it, be it receptacles, lights, appliances, etc. This is a great option for new branch circuits, especially if you are combining GFCI protection (shock protection) with arc-fault circuit-interrupter (AFCI) protection (fire protection).

However, for existing wiring systems, multiwire branch circuits with shared neutrals, and certain sensitive equipment, GFCI breakers may not work correctly. The simple solution is to install GFCI receptacle outlets or other GFCI devices further down the line, or at the end of the line on the branch circuit. Also, there are a bunch of options for portable GFCI devices that help protect people outdoors, on construction projects, when traveling, using a portable generator, or anytime you are at risk of electric shock due to the hazardous combination of electricity and damp or wet locations.