Save your back with this handy shop cart

A full day

Beginner

$51–100

Introduction

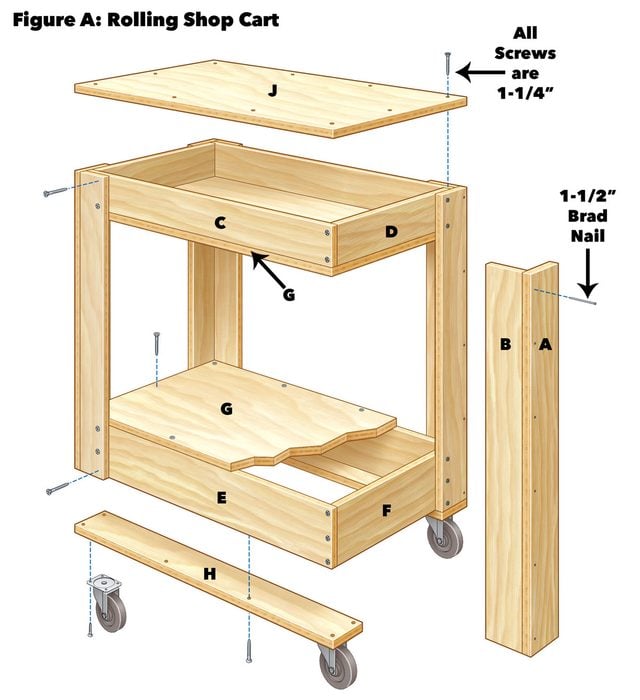

Build a simple rolling shop cart to transport heavy toolboxes and pieces of wood from one end of the shop to the other. All you need is a sheet of 3/4-in. plywood.

Getting Started

Whether your shop is big or small, it’s sure handy to have a cart or two for moving stacks of parts from one machine to another. Carts make an endless journey around a shop, from planer to table saw to drill press to the sander, and on and on. They’re never empty!

Constructing this DIY tool box cart is simple—all the parts are just glued and screwed or nailed together. You’ll need one full sheet of 3/4-in. plywood and a box of 1-1/4-in. screws.

Plus, learn how to tame the clutter and work smarter with these ingenious (and inexpensive!) workshop storage tips you can DIY.

Tools Required

- Air compressor

- Air hose

- Brad nail gun

- Circular saw

- Clamps

- Cordless drill

- Countersink drill bit

- Framing square

- Hearing protection

- Miter saw

- Safety glasses

- Straightedge

- Table saw

Materials Required

- 1-1/4-in. screws

- 2 1/2-in. casters (4)

- 3/4-in. plywood

- Wood glue

Project step-by-step (5)

The Rolling Tool Box

You can use your cart to support your table saw work, so build your cart the same height as your saw. If you want to do the same, buy the casters for your cart before cutting any parts to size. (We recommend using casters that are at least 2-1/2 in. in diameter.) Then measure the total height of one caster and alter the lengths of the cart’s legs as needed.

For a large, printable copy of Figure A and the Cutting Diagram, along with the Cutting List, see Additional Information, below.

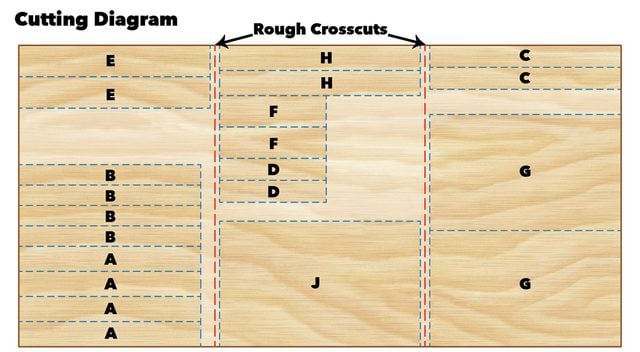

DIY Tool Box Cart Cutting Diagram

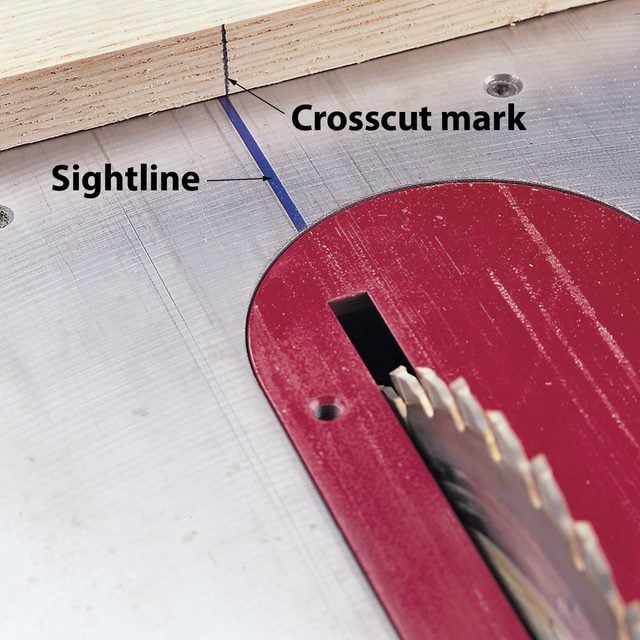

We’ve laid out the parts so you can crosscut your plywood into three 32-in. pieces before having to cut anything to exact size. It’s OK if these crosscuts are rough; a jigsaw or circular saw would work fine. And by following this cutting diagram, you’ll be able to cut all the pieces for the rolling tool box cart from a single sheet of plywood.

The overall dimensions of the rolling tool box cart are 20″ wide x 32′ long x 34-1/4″ tall. All materials are 3/4″ thick.

Cut Leg Pieces to Length

It’s best to use a table saw for ripping the parts and a miter saw or table saw for cutting them to length. After breaking down the plywood into manageable sizes, cut all the leg pieces (A and B). Glue them together, using nails or screws to hold them together while the glue dries. Make sure their ends are even.

Upper and Lower Shelves

Cut the parts for the upper and lower boxes (C, D, E and F) and glue and screw them together. Next, cut the shelf and bottom (G) to fit the boxes and glue and screw these pieces into place. (Adding a bottom to the upper box makes it easier to clamp things to the top of the cart. Without a bottom, you’d only have a narrow 3/4-in. edge to clamp to.) Make sure the shelf and bottom don’t overhang each box or the legs won’t fit correctly. To avoid any overhang, you could cut the shelf and bottom 1/16 in. smaller all around.

Fasten the Cart Together

Fasten the legs to the boxes, using three screws at each corner. Finally, cut the caster supports (H) and top (J) to size and add them to the cart. Fasten the casters using 3/4-in. No. 14 sheet metal screws.

Every home workshop (even if it’s just a sliver of your garage) needs a quality workbench. One of these workbench designs is sure to suit your needs. PLANS INCLUDED.

Additional Information