Customize and finish these super-simple box shelves for any room in the house.

A full day

Beginner

$51–100

Introduction

Organize the clutter. These simple box shelves can hold books, hats, shoes and all kinds of knick-knacks. You can even sit on them!

Super-strong construction

Get ready to learn how to build box shelves! These are amazingly sturdy, thanks to the two-layer, 1/2-in. plywood design. The thickness and the overlapping joints make them strong enough to display or store anything.

We’ve designed these simple wooden shelves for heavyweight storage and incredibly easy construction. It’s fairly easy to learn how to build them, and they’re really versatile. Use them for hats and gloves, books, games and toys, or even laundry supplies. Custom-size them for whatever space you have and whatever needs a home.

You can build one large box from a sheet of plywood and have a bit left over for another. Any veneered 1/2-in. plywood will work, but we suggest birch because the grain doesn’t show through paint. Buy a quart of woodworker’s glue, and 3/4-in. and 1-in. brads for your nail gun. If you don’t have a nailer, you can hand-nail, but it will be a struggle.

You’ll also need fast-drying wood filler. Buy a quart of B-I-N or KILZ primer and a quart of latex enamel paint in the color of your choice. If you choose a gloss finish, be aware if you don’t pay attention to filling and sanding, every single imperfection will proudly display itself.

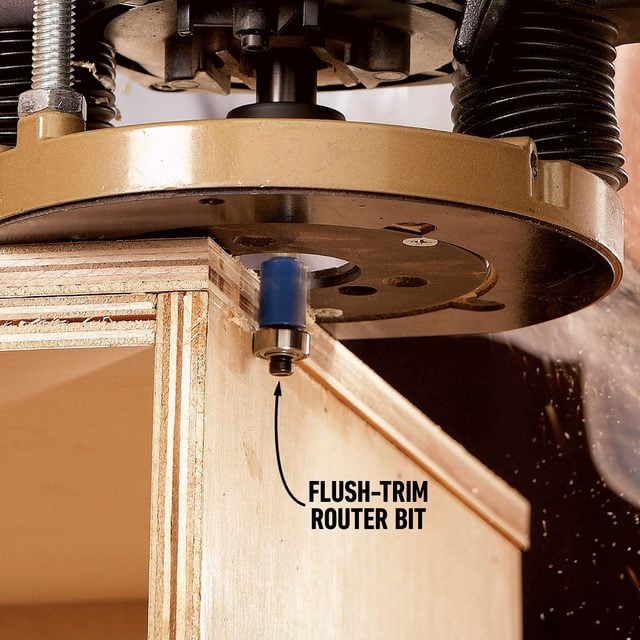

Also pick up some mini rollers (Photo 6) for applying the finishes. And finally, a flush-trim router bit will speed up the final trimming (Photo 4). That way you can cut the outer panels a little long and achieve perfectly flush ends without the hassle of precise cutting.

Figure A: Simple box

Size the box to fit the wall space and objects you intend to put in and on it.

Tools Required

- Air compressor

- Brad nail gun

- Circular saw

- Cordless drill

- Drill bit set

- Framing square

- Level

- One-handed bar clamps

- Paint roller

- Paintbrush

- Putty knife

- Router

- Safety glasses

- Sanding block

- Stud finder

- Tape measure

Materials Required

- 1/2-in. Birch plywood

- Paint

- Primer

- Sandpaper

- Wood filler

- Wood glue

Project step-by-step (11)

Cut out the parts

The first step in building these shelves is deciding how you’re planning to cut them. It’s easiest to rip the parts on a table saw, but you can use a circular saw and a ripping guide. If that’s your plan, use a crosscutting guide when you cut the lengths.

Use fine-tooth crosscutting blades for both types of saws. After deciding on the size of your box, you’ll need to rip two different widths for the box panels.

Rip the four inner panels 1/2-in. narrower than the final box depths, and rip the four outer panels to match the final depth. Be sure to rip enough material to get all of the parts made.

If you like adjustable shelves, drill the peg holes before assembly. Measure the inner box after assembly to get the dimensions for the back panel. Cut the back 1/8-in. overlong in both directions and rout off the excess.

Glue and nail the inner box

Glue and nail the box together, using a framing square for precision. Make the back 1/8-in. larger than the box, then glue and nail it in place and rout any overhangs.

Glue and nail the outer box

Add a second layer of plywood to the top and bottom of the box.

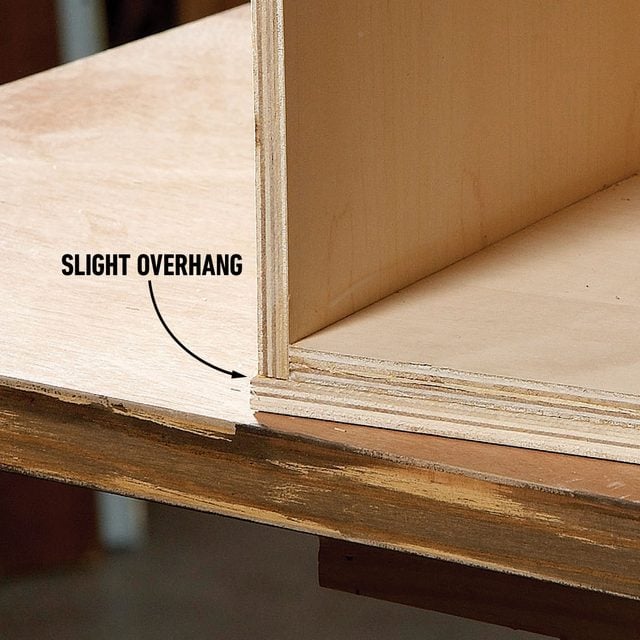

Oversize each panel

To avoid fussy measuring and cutting, oversize each panel by 1/8-in. and cut off the excess later.

Trim the edges flush

Trim the overhanging plywood with a flush-trim router bit. The bit leaves a straight, smooth cut that’s perfectly flush at the ends. Install the end panels using the same method.

Assemble the outer box

Cut the top and bottom outer panels to length, 1/8-in. longer than the box. Apply a bead of glue about 1/4-in. in from the edges and a second bead in a zigzag pattern in the middle. Align the panels flush with the front and with equal overhangs at the ends.

Nail the parts together with 3/4-in. nails. Be careful. It’s tough to fix the damage from nails that miss the mark. If you have clamps, squeeze closed any gaps. A tight joint will reduce the sanding and filling you have to do later.

For a perfect edge, shave the overhangs with a flush-trim router bit. As before, cut the side panels 1/8-in. longer than the box sides, then apply and trim them as you did with the top and the bottom.

Fill gaps and holes

Fill the plywood edges as well as nail holes and dents. Use a fast-drying filler so you can sand the patches right away.

Prime and paint

Sand the exposed plywood edges until they’re smooth, first with 80-grit paper and then 120-grit. Then work wood filler into all the edge grain, nail holes and dents. After the filler sets, sand everything flat with 120-grit paper.

Brush primer into the inside corners and then roll primer onto the rest of the box. After it dries, voids that didn’t get filled will be apparent. So fill anything you missed, and then sand and prime those spots again. Brush and roll on two coats of paint, lightly sanding between the coats with 220-grit paper.

Locate wall studs

Outline the box location on the wall and mark the wall studs. Use the outline to mark the pilot holes and then drill them through the back of the box.

Fasten with screws

It’s imperative you screw these boxes to at least two wall studs; no wall anchors of any kind will pass muster. Use at least two 3-in. deck screws near the top and two more at the bottom into separate studs.

If more studs are available, use those, too. You’ve just learned how to build shelves. You don’t want that hard work to go to waste by failing to properly mount them to the wall.

Vertical box with adjustable shelf

Add an adjustable shelf by drilling peg holes, evenly spaced in the inner box sides. Drill before assembling the box. Once it’s complete, you can put it to work.