Multiple Days

Beginner

$600-700

Introduction

Assemble this easy-to-build storage locker to use as a lawn mower shed, garden storage shed or both! This storage locker is low and compact, yet spacious enough for lawn mower storage, plus all your long-handled tools and gardening materials.

Outdoor storage cabinet project overview: Benefits, time and materials

Lawn and garden tools present a paradox: You can never find the right tool when you need it, then when you aren’t looking for it, it’s in your way. This simple-to-build shed which is the perfect outdoor storage locker that solves both problems. It stores tools so they’re easy to find, and it does so in a convenient location in your yard so they’re not cluttering your garage.

The locker’s 4 x 8-ft. footprint provides ample room to store space-hogging items like walk-behind lawn mowers and snowblowers. Long- and short-handled garden tools, lawn treatments and potting materials also fit nicely inside.

In this article, we’ll show you how to build this attractive outdoor storage locker using easy construction techniques. It’s a great project for beginners looking to expand their building skills.

You can build and paint this locker in a weekend, although you might need another half day to give the pressure-treated trim a second coat of paint. The straightforward construction requires only basic power tools—a circular saw with a standard carbide blade and a drill. An air compressor and nail gun aren’t necessary but will make the framing and trim work easier (and faster!).

We used fiber cement panels for siding because they resist rot and hold paint well (the panels come primed). If you substitute plywood panels, be aware that they’ll eventually rot along the bottoms where they’re in ground contact. We chose corrugated plastic panels for the roof because they let in light and are easy to install. Materials for our locker cost about $600.

A Clear Roof Lets In the Sunshine

These clear plastic roof panels let in sunlight so you can easily see inside. They’re lightweight, faster to install than asphalt shingles and don’t need sheathing underneath. You can cut them with a carbide blade in a circular saw. And best of all, they won’t peel or tear like shingles, and they last for decades. The downside is they’re not in stock at most home centers. You may have to special-order them.

Tools Required

- Caulk gun

- Chalk line

- Circular saw

- Drill bit set

- Drill/driver - cordless

- Hammer

- Level

- Safety glasses

- Shovel

- Speed square

- Tape measure

- Wheelbarrow

Project step-by-step (7)

Outdoor Storage Locker Details

Find a site and gather materials

A flat or nearly flat site (less than a 6-in. slope over 6 ft.) is ideal for this storage locker. You can add gravel or stack up several sleepers on one side if your site has a steeper slope, but the doors need 3 ft. of space to open. If the locker faces a steep slope, you’ll have to dig away the ground in front of the doors so they can fully open. You can find all the materials except perhaps the roof panels at most home centers. We used Sequentia panels from Crane Composites, which are available in several colors and clear. Buy treated trim material a few weeks early and let it dry. Otherwise, the wet wood will shrink and won’t hold paint. Make sure to use galvanized nails or exterior screws because they won’t corrode.

Assemble the floor

Level the sleepers

Lay sleepers over gravel to create a flat foundation fast. Add or remove gravel until the sleepers are level.

Attach the floor

Screw the floor framing to the sleepers at each corner. Then double-check the floor for level.

Start by digging parallel trenches 10 in. wide by 6 in. deep and centered 3 ft. 6 in. apart. If the ground is slightly sloped (like ours was), dig out any high areas between the trenches so you can (later) place a level across the sleepers.

Fill the trenches with pea gravel so they’re roughly level. Then cut treated 2×6 sleepers to size and set them over the gravel so the outside edges are 4 ft. apart. Place a 4-ft. level over one of the sleepers. Level it, then adjust the second sleeper until it’s level with the first (Photo 1).

Frame the floor on your driveway or another flat surface with treated lumber using 16d nails or 3-in. screws, following Figure A on p. 49. Lay a full sheet of 1/2-in. 4 x 8-ft. treated plywood over the floor frame. Adjust the floor frame so the corners are aligned with the edges of the plywood, then fasten the plywood using 8d nails or 1-1/2-in. screws. Snap chalk lines at the floor joist locations to make them easy to find. Drive fasteners every 6 to 8 in. along the edges and every 12 in. in the field.

Place the floor over the sleepers, align the corners, then drive 3-in. screws at an angle into the sleepers (Photo 2).

Frame the walls and roof

Erect the walls

Build the walls and screw them to the floor. Attach temporary bracing to hold the walls plumb.

Install purlins

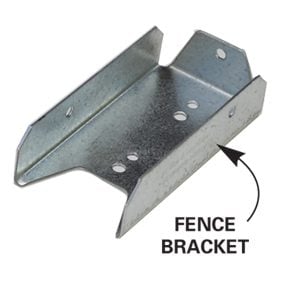

Install the purlins using fence brackets for the butt joints.

Install the purlins using fence brackets for the butt joints.

Photo 4A: Close-up of fence bracket

Inexpensive fence brackets make fastening the purlins easy.

Install the rafters

Nail the rafters to the header and align them with the top of the back wall to create a flat plane for the roof.

Build the front and back walls following Figure A. Use treated lumber for the bottom plates and the door trimmers. Attach the assembled walls to the floor with 16d nails or 3-in. screws. Drive the fasteners near the outside edge to ensure they go into the underlying framing, not just into the plywood.

Have a helper place a level on a stud near one end of a wall. When the wall is plumb, fasten temporary bracing between the wall and the floor (Photo 3).

If you’re not an experienced builder, toenailing the purlins into place can be tricky since it’s hard to drive nails and keep the purlins at their marks. Avoid this frustration by using fence brackets. Nail them to the outside studs on the front and back walls with 8d nails, keeping the tops 1-1/2 in. above the top of the shelf supports. This keeps the tops of the purlins and the shelves (installed next) aligned for a flat surface.

Cut the purlins to size, set them into the brackets and drive 4d nails through the bracket holes (Photo 4). Cut the shelves to size and fasten them with 8d nails. It’s important to install the shelves now since they won’t fit after the siding is on.

Set the header in place, flush with the outside of the front wall. Drive 16d nails or 3-in. screws through the underside of the top plate into the header every 6 to 8 in.

To mark the angled end of the rafters, hold them in place alongside the header and the back wall. Mark the rafters and cut them to size. Use the fence brackets to hold the rafters in place on the back wall.

Nail the brackets so the top is slightly above the top of the wall. Nail the rafters in the brackets. Hold the opposite end flush with the top and side of the header, then face-nail it with two 16d nails or 3-in. screws.

To frame the roof, install the rafters (Photo 5). Cut two mid-beams at 93 in. Mark the rafters at the one-third and two-third distances between the walls. Place the mid beams at the marks and attach them with 16d nails or 3-in. screws.

Side with fiber cement

Install the siding

Cut the fiber cement panels to size and nail them up.

Close-up of panel corner

Support the heavy siding panels with temporary nails placed 1-1/2 in. from the bottom of the floor framing.

Use a carbide saw blade for cutting the fiber cement siding panels in a circular saw—and be sure to wear a mask. Cutting cement siding is extremely dusty. And be prepared—the 4 x 8-ft. panels are heavy.

We kept the siding 1-1/2 in. from the bottom of the locker to avoid direct contact with the ground.

Cut panels for the back and front walls following Figure A. Install the front panels, starting at a corner. Then install the back panels so they butt together over the middle stud on the wall. Don’t worry that the panels don’t fully cover the corners. You’ll cover them later with trim.

Nail the panels with 8d nails. Drive the nails snug with a smooth-face hammer so you won’t mar the siding. Drive nails straight, not at an angle. Keep nails 3/8 in. from panel edges and 2 in. from corners. Hold the side panels in place (don’t nail them yet) and mark them along the top of the rafters. Cut them to size and nail them into place (Photo 6).

Add the trim

Nail on the trim

Trim the outdoor storage locker, starting with the fascia. Then add the corner boards.

Painting along the roof panels is a pain, so it’s best to paint the trim now. If you’re using two colors, paint everything—you won’t have to cut in with paint later.

Install 1×4 fascia along the top of the locker. Start with the back, then add the sides, then the front. Hold each piece in place to mark the angle and cut it to size, then attach it with 8d nails before moving on to the next piece. Then cut and install 1×3 fascia over the 1×4 fascia.

Use treated lumber for the corner boards since they’re in ground contact. Cut the corner boards to size and nail them into place with 8d nails. Nail the boards on the sides first, then install the boards on the back and front walls, overlapping the side boards (Photo 7).

Cut and nail treated 2×4 door supports flush with the door opening, butted against the fascia. Use 16d nails. The door supports stick out a little proud of the fascia, but the extra thickness is needed to support the doors.

Install the clear roof

Add the roof panels

Lay a heavy bead of caulk over the plug strip before screwing on the roof panel.

Before installing the roof, place wooden panel plugs flush with the outside of the fascia along the front and the back walls. Drill pilot holes through the peaks and nail the plugs into place with 4d nails. The plugs conform to the shape of the roof panels, sealing the openings to keep out the birds and the bees. For roof support along the sides, install supports (quarter round).

Cut the 9-ft.-long roof panels in half with a circular saw. Run a generous bead of silicone caulk along both plugs for 27 in., then set the panels in place so there’s an equal overhang on the front and back and about 2 in. on the side.

Drill 1/8-in. pilot holes through every third peak at the plugs and the mid-beams, then insert 1-1/2-in. hex-head panel screws.

Caulk along the edge of the installed roof panel and the panel plugs (Photo 8). Then install the next roof panel. Overlap the panels by 3 in. When you get to the end, cut the last panel to size.

Hang the doors and paint

Hang the doors

Hold the doors in perfect position with shims. Then screw on the hinges.

Build the doors using treated lumber and following Figure B. Use scrap siding panels for the door panels since the middle 1×4 hides the gap. Assemble the doors with 6d nails driven at a slight angle so they don’t poke through the opposite side. Make sure the seams in the top and bottom scrap pieces are aligned before nailing them into place.

If you haven’t painted the locker yet, now is a good time. Install the doors. Start by nailing a scrap piece of wood in front of the opening so the top is 1-1/2 in. from the bottom of the locker. Drill pilot holes and attach heavy-duty door hinges to the top and bottom of both doors. Set both doors in place over the scrap lumber. Insert shims so the doors don’t pinch at the top and side, then attach the hinges to the door supports with screws (Photo 9). Add handles and a lock as desired.