These snow blowing tips will help you maintain and operate your snow blower for maximum efficiency and safety. Read these tips thoroughly—there are some you'll want to do before you're buried in snow.

13 Snow Blowing Tips That Make Snow Removal Quick and Easy

Snow Blowing 101

Running a snow blower seems like a skill you could master in two minutes. But we wondered: If it’s really that simple, why are there 6,000 blower-related injuries in the United States every year? And why do repair shops get overwhelmed after a big storm?

To get answers, we talked with experts at all the major manufacturers?as well as the guys who fix blowers. It turns out that operator error is the No. 1 cause of clogs and breakdowns, and improper clearing of clogs is the most common cause of injuries. The experts shared some great tips on how to avoid both. So even if you’re an experienced snow blower operator, read on.

Don’t Wait for it to Stop Snowing

One common snow removal mistake people make is waiting for it to stop snowing. The truth is that you should start clearing the snow before it reaches 6 in. Sure, you’ll spend more time snow blowing, but your machine won’t have to work as hard, and it’ll throw the snow farther. That’ll reduce the height of the snowbanks flanking your driveway.

Throw Snow As Far As You Can

Avoid throwing snow only partway off the driveway and then throwing it a second time. That just creates a heavier load for the blower. There are four ways to get the maximum throw: Take smaller bites of snow, run the blower at full rpm but at a slower ground speed, adjust the chute diverter to its full raised position and blow with the wind.

Prepare Your Property Ready for Snow

You can make snow removal that much easier if you take some time to winterize your driveway and sidewalks. To start, inspect your property. Remove rocks, dog tie-out cables, extension cords, holiday light cords and garden hoses. Then stake out paths that run near gardens so you don’t accidentally suck up rocks and garden edging with your snowblower. Mark your walk and driveway perimeters by pounding in driveway markers. If the ground is already frozen, just drill a hole using a masonry bit and your battery-powered drill.

Watch Out for Half-Buried Newspapers

A frozen newspaper is the leading cause of machine jams. It can break shear pins or belts and damage expensive auger and impeller components. A fresh layer of snow over newspapers makes them hard to see, and they’re easy to forget. So protect your machine by scouting the area before you hit it.

If you do suck up a newspaper, shut down the engine and remove it with a broom or shovel handle, but never with your hands. If you can’t remove the paper, take your machine to a pro, who will charge a whole lot less than even the cheapest surgeon.

To avoid any other hiccups while removing snow, use these tips to fix a snow blower that won’t start.

Take Smaller Bites to Avoid Clogs

It’s tempting to crank up the speed and plow right through it. That’s the single best way to clog your machine and wear out (or break) the drive belts. And when you consider how long it takes to constantly stop and unclog the chute, ramming at full speed doesn’t actually save any time. Worse yet, improperly clearing a clogged chute is dangerous, and the most common cause of snow blower?related injuries.

Instead of making a full-width pass through the snow, manufacturers recommend taking smaller bites; about one-third to one-half the width of the machine. It’s faster than slogging through a full path of heavy snow and it’s easier on the machine. Another reason it’s a better snow-blowing technique is that it allows the machine to throw the snow farther.

Start With Fresh Fuel

Stale gas is the No. 1 cause of hard starting. So don’t use what’s left in the lawn mower can. It’s better to dump that summer blend into your car’s tank, then refill the can with winter blend, which is more volatile and provides better starting.

Cool Off, Then Gas Up

If your snow blower runs out of gas halfway through a tough job, you’ll be tempted to refill it right away. But think about this: The engine is hot and the gas tank sits right on top of that hot engine. Even worse, you’re standing right over the machine holding a gallon of gas.

Snow-blower fires happen often enough that the manufacturers strongly recommend that you let the engine cool for at least 10 minutes before refilling. Take that opportunity to grab a cuppa joe or hot chocolate and warm up your fingers and toes. Then, once your personal tank is refilled, refill your snow blower and carry on.

Add Stabilizer to Fresh Fuel

Follow the fuel stabilizer dosing recommendations on the bottle label. Add the stabilizer to the gas can right at the gas station so it’ll mix up on the way home. Or, add a premeasured packet to the gas can before filling it with gas.

Switch to Synthetic Oil for Easier Starting

Small engines typically have to reach at least 400 rpm before they’ll fire up. But traditional motor oil thickens when cold, making it much harder to reach that 400-rpm threshold. Synthetic oil allows the engine to spin faster when you yank the cord, so it starts with fewer pulls. So when you change the oil in your snowblower next, switch to synthetic.

Don’t Forget Pre-Season Maintenance

Get your snow blower ready for action by installing a new spark plug, changing the oil and checking the condition of the belts. Replace the belts if you see cracks, fraying or glazing or notice that chunks are missing. Replacing the spark plug? Consider an iridium spark plug.

Next, sand any rusted areas and repaint. Once the paint cures, apply a high-quality polymeric car wax to all painted surfaces. The wax will shed the snow and water and protect the paint. And, wax the inside of the chute to help prevent clogs.

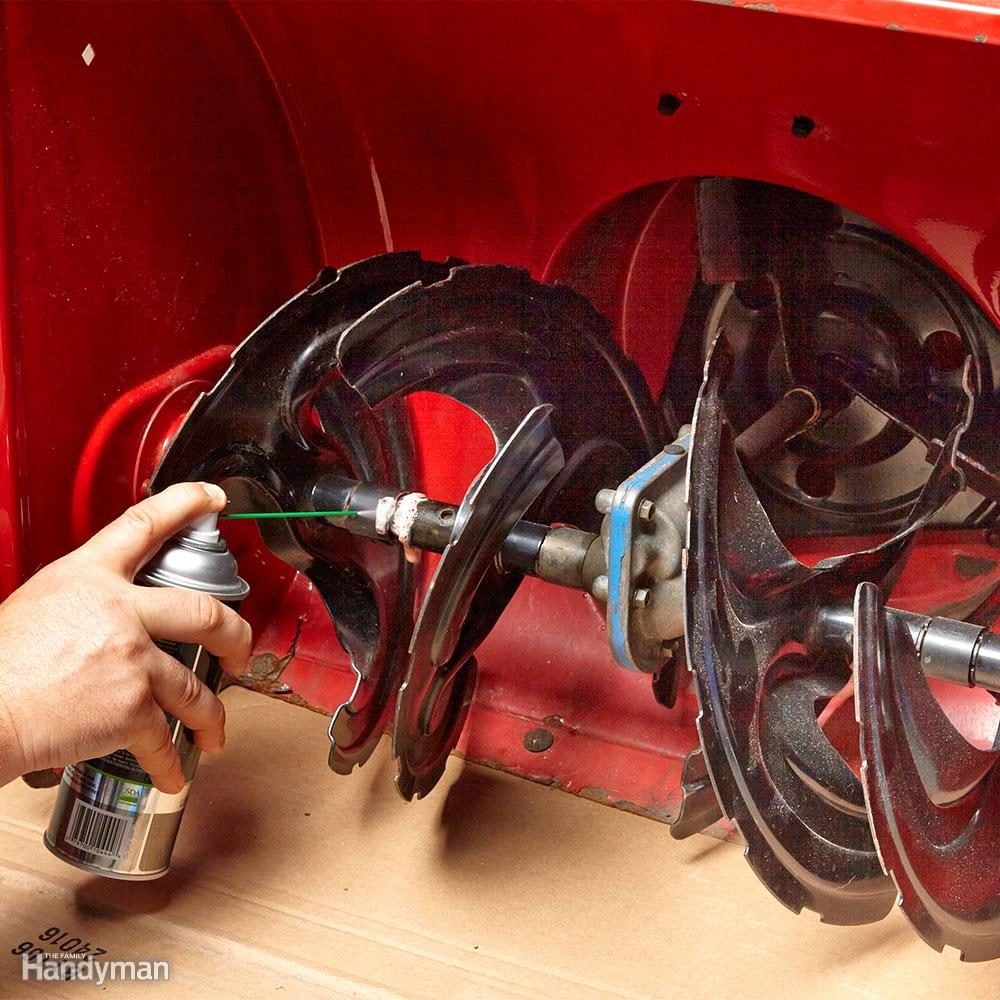

Then consult your owner’s manual to find the lubrication points and the recommended lube. If the type of lube isn’t listed, here’s some general guidance: Use motor oil on metal linkage joints, gears and cables, but dry PTFE lube on plastic parts (knobs, gears and chute). Spray the auger, second-stage impeller and chute with silicone spray to prevent snow from sticking.

Buy Parts Before You Need Them

Belts and shear pins always break on a Sunday night in the middle of a blizzard. So buy replacement parts at the start of the season when everyone has them in stock. If you break a shear pin and try to improvise using the wrong shear pin, or worse yet, an ordinary bolt, you risk major damage that can easily cost you $200. You’ll need to change the belt in your snowblower from time to time too, so grab set of belts and a few extra shear pins.

Also make sure you have the right size of wrenches and sockets and the correct size pin punch to drive out the broken pin. Then assemble a parts and tool kit.

Prevent Major Auger Damage

The drive shaft applies torque to the shear pin, which then applies it to the auger. However, if the auger rusts to the drive shaft, they’ll become one and the shear pin will never break. If that happens, the auger clog can cause major damage to the machine. Lubricate the drive shaft to prevent it from rusting to the auger. Remove shear pins and lubricate the drive shaft with lubricating oil. Then spin the auger to spread the oil along the length of the shaft. Reinstall shear pins.

If you’re unable to remove the snow on your own, then you can always get professional help. Here, find out the cost of snow removal.