There's a lot to consider when attempting to purchase the best plywood for a project. Check out this uber-comprehensive plywood buying guide.

What to Know About Buying the Best Plywood

When you’re buying plywood or plywood sheets for any project, shop wisely. Your choices of plywood will have a huge impact on the building process and the results. This story will help you decide exactly what you need and help you avoid common plywood pitfalls.

Types of plywood: Veneer Core

Veneer core plywood is made up of many layers of hardwood bonded together. The layers are assembled with alternating grain direction, called cross-banding. This makes a strong, rigid, lightweight sheet with excellent screw-holding capability. Because of these qualities, veneer core is my first choice in most cases.

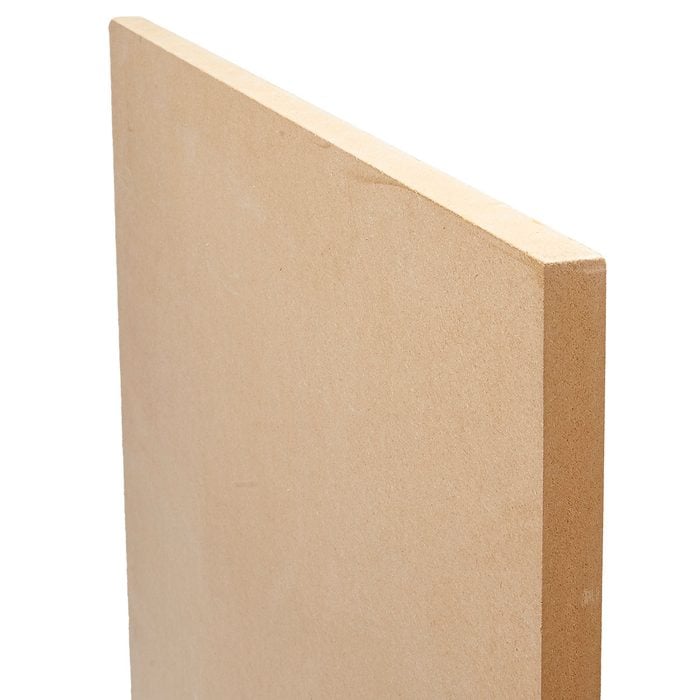

MDF Core

MDF core plywood has a few advantages over veneer core. The thickness is more consistent; it machines well; the edges are solid, and MDF gives a smooth, even surface for the face veneer. It’s also more stable and it’s typically flatter. However, MDF core plywood isn’t as strong as veneer core, it doesn’t hold fasteners as well and it’s heavy. But if I’m making one-piece doors, I’ll choose MDF core plywood sheets every time because of its flatness and stability.

Particleboard Core

Particleboard core plywood is the least expensive option. Like MDF core, it’s flat and stable with consistent thickness. But particleboard core plywood is a bit worse in the screw-holding category. Also, it’s a special-order product, at least from my lumberyard, whereas MDF core is readily available.

Combination Core

Combination core plywood weds the best attributes of MDF core and veneer core. The center cores are cross-banded hardwood, providing strength, light weight and screw-holding capability. The outer cores are MDF, giving a flat, uniform surface for the face veneers. However, combination core plywood is a compromise: It doesn’t have the screw-holding capability and rigidity of veneer core, or the flatness and stability of MDF core.

Lumber Core

Lumber core plywood consists of edge-glued strips of wood, usually basswood. On both sides of the core, there’s a cross-banded veneer, then the face veneer. Like veneer core, it has excellent screw-holding capability, strength and rigidity. But it’s considerably more expensive and harder to find than veneer core, so I almost never use it. However, this plywood a good choice for long shelves.

Baltic Birch and Appleply

Baltic birch and ApplePly plywood are top-notch veneer core plywoods, which you’ll only find at a lumberyard. Their 1/16-in.-thick core veneers offer better stability than typical plywood with 1/8-in.-thick core veneers. The raw edge is attractive when finished and often used as a design element. Baltic birch or ApplePly plywood is my first choice for drawers and shop jigs. ApplePly is available in thicknesses from 1/4 in. to 1-1/2 in., and in many face veneer species.

How veneer is cut: Rotary Cut

Rotary-cut veneer is peeled from the log like paper towels from a roll. It produces a wide, “loud” grain pattern.

Plain-slicing

Plain-slicing produces a repeating pattern, typically showing large “cathedrals” in the grain.

Rift-sawing

Rift-sawing produces veneer with tight, straight lines.

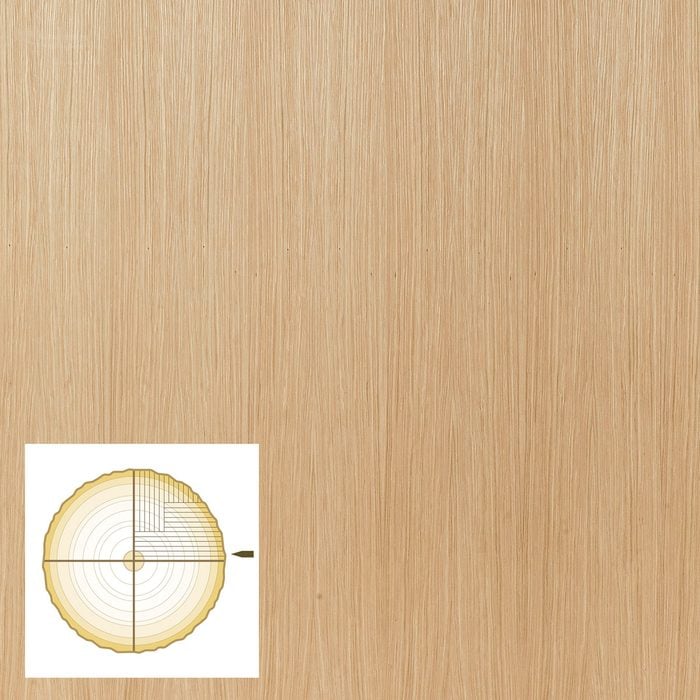

Quarter-sawing

Quarter-sawing produces veneer with the same tight, straight lines as rift-sawing but includes the signature “ray flecks.”

Check for plywood flatness

Don’t expect perfection—you probably won’t find it. Just try to find the best of the pile. Sight down all the edges just like you’d do if you were buying 2×4 studs. Sometimes, plywood sheets are warped in multiple directions, resembling a potato chip. Leave these for some unlucky, less-informed buyer. If you’re buying 1/4-in. plywood, don’t worry about flat and straight; it won’t be either. But you’ll likely fasten it to structural parts, which will keep it flat.

Inspect the edges

Examine the edges of plywood and inspect the different layers of veneer. They should be straight and of uniform thickness and have few, if any, voids. If you see a lot of voids, there’s sure to be more throughout the sheet that won’t be visible until you cut it.

And avoid overlaps. On high-quality plywood sheets, core veneers are each one piece, or one full layer. But sometimes on less expensive plywood, two or more pieces are used to make up a single layer. Instead of being cut to fit each other where they meet, the edges overlap and are just pressed to the thickness that that piece of core veneer is supposed to be. This can result in an undulating surface.

Watch for buried treasure

The most beautifully figured face veneers will be at the lumberyard. But when I’m at the home center, I like to check out the back faces of the plywood or even plywood that’s meant for underlayment. Because most people look for consistency of color and grain, there are some striking veneers that get written off as ugly. Quite often, something catches my eye that could be a really cool design element.

Can you special-order plywood?

Some home centers will special-order many different species, core options and veneer cuts. But beware: You won’t be able to look at the actual plywood sheets before buying, and you probably won’t be able to return or reject them unless they’re damaged or otherwise unusable. If it’s just that you don’t like the grain pattern, you’re probably stuck with it. Also, there may also be a minimum quantity you need to buy.

Shop the home center for convenience and savings

Baltic birch is a premium plywood found at lumberyards. A 3/4-in., 5 x 5-ft. sheet has 13 core veneers and costs about $70. Some home centers carry a similar product, called “classic birch.” A 3/4-in., 4 x 8-ft. sheet has 10 core veneers and costs $50 to $60. It’s strong with good screw-holding capability, making it a good, affordable alternative. It’s perfect for less visible cabinet parts, drawers and shelving. As for other plywood sheets, home centers have a more limited selection, carrying mostly veneer core (maybe MDF core), grade B2 and lower. Face veneer cuts are typically rotary cut or plain sliced, and in-stock species will usually be red oak, birch and maple. But the home center is a good option to save a little money.

Which plywood can you paint?

For projects I’m going to paint, I like MDF (medium-density fiberboard) or birch. B-grade birch or lower is fine. Sometimes, you’ll even see plywood classified as “paint grade.” Birch is close-grained with a smooth texture that doesn’t show through paint. With an open-grained species like oak, the grain is visible under paint. MDF, of course, has no grain pattern, making it a good choice for painted projects. But for structural parts, I like birch veneer.

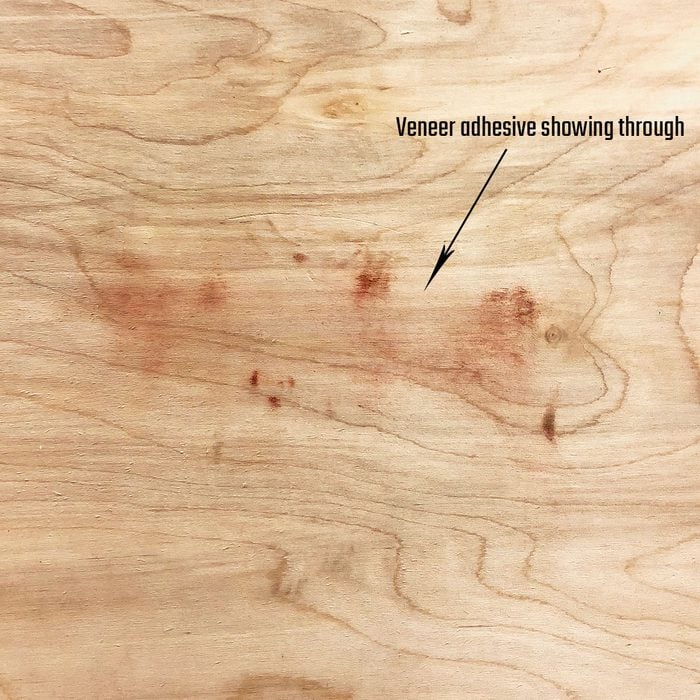

Can you sand plywood?

All plywood needs at least light sanding before finishing. Sometimes, the face veneer on home center plywood is so thin that the pink veneer adhesive shows through. On several occasions, I’ve had birch veneer turn translucent after light sanding with 220-grit paper.

If you suspect that the veneer is ultra thin, don’t use a power sander. Just sand by hand.

How to get the bow out of plywood

Admit it: You’ve tried flattening sheets of plywood. I have too. I’ve tried weights, clamps, wetting down the concave side, sun-drying the convex side and gluing opposing bowed sheets together. Nothing seems to work with any reliability. If the core veneers weren’t in a perfect state of equilibrium and all in harmony when they were bonded together, the sheet has little chance of flattening out. The only recourse is to save the flattest sheets for the largest parts and use the worst sheets in smaller components, minimizing any curvature.

Watch out for plywood damage

You can often cut around minor damage in an otherwise good plywood sheet (if you can, you might even be able to get a discount). But sanding out deep dents (above) isn’t an option. You may not be able to sand out stains either. The purple stains shown result from a reaction between oak tannin and steel.b